SUCCESS STORY

Minimizing blockages and delivery delays by reducing search efforts while enabling seamless shipping processing for end-users

Read More Download PDFThis leading global manufacturer of high-quality construction equipment and compact machines offers a range of products and services for professional users in construction, gardening, landscaping, and agriculture, as well as municipalities and industrial companies in sectors such as recycling.

The search for the right resource can quickly become a “search for a needle in a haystack” at an international construction equipment manufacturer group, where equipment ready for dispatch is stored pending collection in respective yard areas with spaces ranging from 5,000 to 55,000 m². The same outdoor space is used as a buffer area for interim storage of unfinished products for production. Additionally, excavators pass through multiple stations in the yard, regularly resulting in high search efforts and costly waiting times. Congestion and unplanned stops hamper overall productivity in the production and handling process.

It is not uncommon for unfinished components to be lost in the yard or forgotten in the production flow resulting in unnecessary replenishment requirements and delays in the production flow, which in turn leads to completion and delivery delays. Thus, resources in the buffer zone remain partially unused leading to wastage due to incorrect storage in the yard. As a result, the transport flow is unnecessarily increased, highly inefficient, and time and cost intensive.

Optimized transport order management and minimization of post-processing efforts are essential to the company's efficiency. Thankfully, new technological advances are making it possible to streamline this process and improve results.

Digitizing process workflows and using real-time analytics can help reduce process cycle times, thus reducing the likelihood of process blockages and delays. Additionally, by implementing these technologies, organizations can better optimize production flow and resource utilization. As a result, fewer product resources will be needed in the buffer zone, and wastage due to incorrect storage in the yard will be reduced. Consequently, the transport flow will be more efficient, saving time and money. Virtual process workflows and real-time analytics are therefore powerful tools that can help improve productivity in the production and handling process.

In order to keep up with the demand, it is necessary to have a well-oiled machine. However, when parts of the process are not working together, it can create a ripple effect that can impact the whole operation. One such example is when empty runs and long throughput times increase the unbalanced relationship between service level and costs incurred. The result is high use of resources and low transport performance. Not only does this put a strain on the personnel, but it can also be dangerous, as they may be searching for components in passing traffic.

It is a big challenge for yard logisticians to keep track of all resources, their status, and movements. Until now, process corrections could only be made slowly and through inaccurate estimates; there was simply a lack of virtualization of material tracking and synchronization of logistics processes (warehouse and yard) with ongoing production. Virtual process workflows and real-time analytics have the potential to reduce process cycle times by allowing for more accurate predictions and better decision-making. This helps to create a more efficient process that saves time and money.

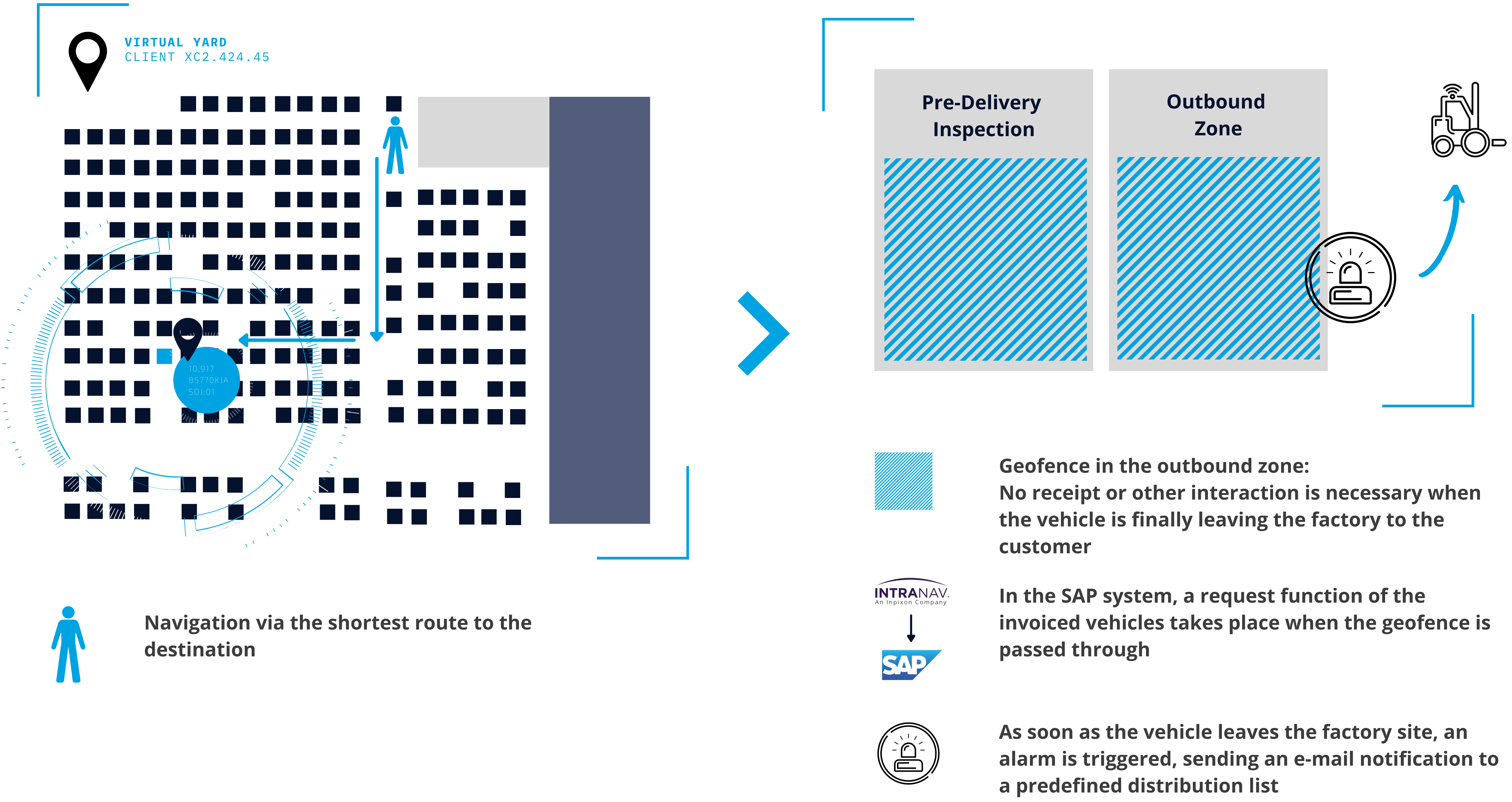

In the outbound process, minimizing search times in the yard is essential because the buffer area of the finished products changes regularly. To optimize and simplify the entire handling process - from pre-delivery inspection to shipment to the customer - an RTLS solution with navigation is needed for fast and timely dispatch. Real-time driven outbound processes, such as issuing invoices via SAP, scannerless status recording for shipping, and customer and factory notifications as soon as product leaves the plant, can reduce process cycle times. By automating these outbound processes, companies can improve their bottom line and better serve their customers.

Since the production of one of the plants has already been digitized by INTRANAV and the control of the variant production has been automated by real-time data-driven process solutions, the extension of the Digital Twin to the yards was the next logical step. This would enable our customer to guarantee an efficient organization of all logistic processes for the production and outbound process. In addition, they were looking for a solution that would allow existing telematics systems, which are already integrated in the construction machines, but also additional outdoor tags, to be connected to an RTLS platform as a hybrid RTLS solution. Our virtual workflows and real-time analytics reduce process cycle times while providing enhanced situational awareness for all stakeholders involved in the process. This allows for a more efficient and cost-effective production process overall.

Real-time tracking and positioning of finished and unfinished products on the yard

Yard navigation and scannerless outbound/shipping processing

Identify the shortest route to the product.

Removal of unnecessary interactions with scanner-free exit processing in the outbound zone.

An automatic alarm triggered by a vehicle leaving the facility sending a notification to the customer or distributor.

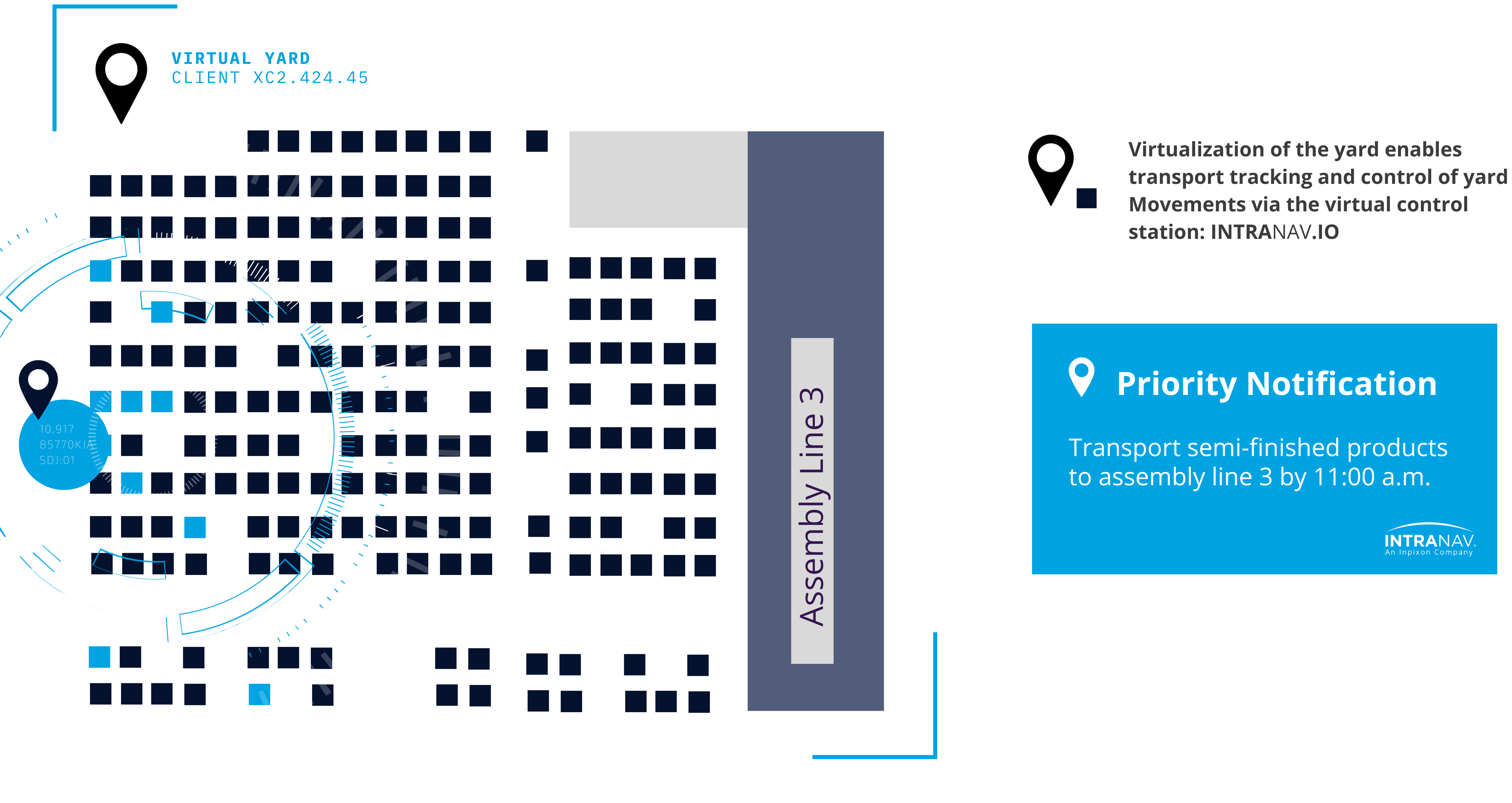

Alerts and process prioritization

A real-time location overview of all construction machines, load carriers, and persons in the yard with search functionality to locate misplaced, obsolete or out-of-zone storage with ease.

Alerts to notify personnel of undesirable situations

System association of tags with the FAUF (INTRANAV & SAP)

Association of the FAUF with tag labels or telematics module for safe, continuous order tracking in the yard.

Analysis and optimization of idle and throughput times

Analysis of bottlenecks with KPI reconciliation including dwell times, cycle time, stops, malfunctions, delays, process length, or the total time required for a complete cycle.

Safety management & collision avoidance

Loading and transport traffic detection in the immediate vicinity of vehicles and persons.

Acoustic warnings or display indications to avoid hazardous situations.

Reducing search and wait times for construction equipment is always a top priority for manufacturers. To help achieve this goal, we implemented our INTRANAV yard management solution. This includes equipping excavators and finished products with our INTRANAV.RTLS AssetTAG+, which is designed for high-performance supply chain tracking and seamless transition from indoor to outdoor tracking.

With this solution in place, the entire yard can be virtualized, making it easier to find and retrieve equipment when it's needed. In addition, the INTRANAV Yard Management Solution provides real-time visibility into the location of assets and inventory, allowing for more efficient utilization of resources. As a result, our customer was able to improve their bottom line by reducing search and wait times while increasing productivity.

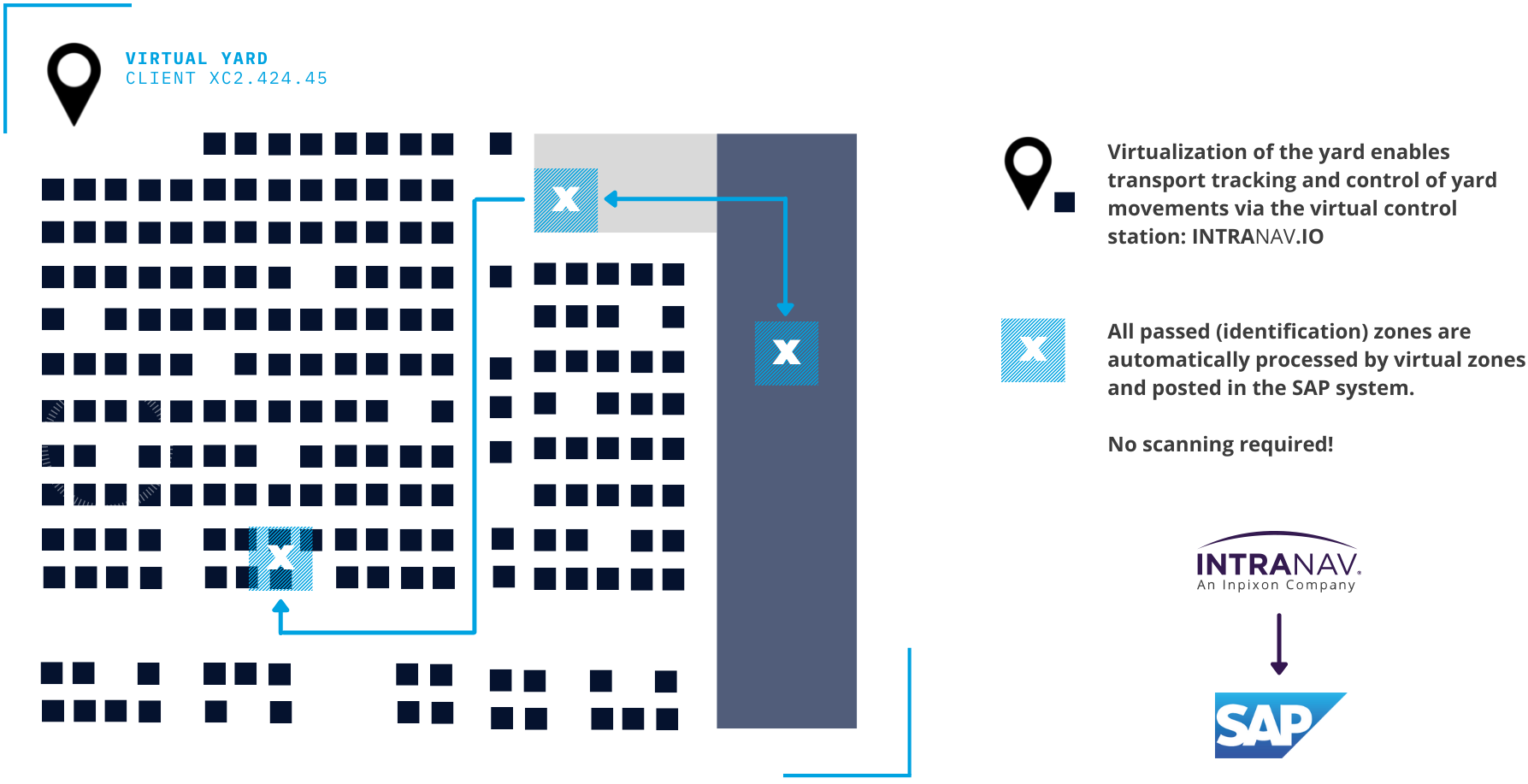

Thanks to its multi-modal tracking technology based on GPS, Bluetooth, and Wi-Fi, it enables global supply chain tracking, and integrated sensors reliably monitor the condition of excavators and semi-finished products. INTRANAV.IO virtualizes and manages yards with real-time vehicle location data as a real-time digital twin. The integrated telematics modules are connected to the INTRANAV.IO system via the open API, enabling INTRANAV to provide a hybrid real-time tracking solution and again saving our customers costs in equipping additional hardware. With INTRANAV.IO assets are monitored in real-time, allowing informed decisions about supply chains. In addition, the digitization of a yard ensures efficient management of resources and improved coordination between connected teams.

Complete digital capture of the flow of goods in the yard area and real-time process optimizations have the potential to increase cost savings and quality improvements. In particular, a real-time inventory overview and search function increase the availability of semi-finished and finished products. Thanks to the virtual mapping of yards, assets can be found immediately without any risk of confusion, while at the same time capacity planning is possible at a glance.

To keep track of all the different excavators in the yard in real-time, the tags (or the telematics module) need to be associated or "married" with the excavator's FAUF QR code in the INTRANAV.IO platform and SAP. This requires that the vehicle be scanned. INTRANAV recognizes whether it is a telematics module or an INTRANAV.AssetTAG+. The personnel will be notified of this via a corresponding dialog box. The tag is then attached with a self-releasing cable tie. By driving the TAG into a geofence, INTRANAV automatically triggers the marriage process in the system. This way, you can call up the real-time position and associated documents of any device using the INTRANAV.IO platform.

INTRANAV provides an IoT sensor-based RTLS solution that tracks and records objects in real-time as they move from their starting point, though all intervening notes (warehouse levels/buffers) to their destination. During this process, all objects to be tracked are automatically recorded in the SAP system at all nodes through geofencing and auto-identification, which optimizes the entire material and transport flow.

Having an efficient system in place to manage storage and materials is crucial for any business, but it can be especially difficult for those in the manufacturing and production industries. With so many moving parts, it's easy for things to get misplaced or forgotten - but that can lead to big problems down the line. This is where INTRANAV comes in.

Our system is designed to help businesses keep track of everything in their yards, from materials to resources, and to alert employees when something isn't where it's supposed to be or if a specified storage time is exceeded. This eliminates costly mistakes, reduces capital and operating costs, and ensures smooth operations. It also helps proactively prevent resource aging, damage, and loss.

Intelligent process prioritization with data reconciliation of the ERP and PP systems helps to optimize production by taking into account factors such as delivery plans and schedules, ensuring work-in-process and associated transportation tasks are being carried out according to delivery dates and production time limits and production targets are being met.

In a fast-paced production or logistics environment, it's critical that personnel are quickly and effectively notified of any process-critical situations. Warning messages help to increase resource utilization and improve on-time delivery by ensuring that drivers and other personnel are aware of potential delays. In addition, acoustic warnings and display messages help to avoid dangerous situations such as collisions or entering danger zones. This significantly increases safety in the yard and helps to avoid accidents. By using warning messages, production and logistics environments can improve efficiency and safety for all personnel.

Our client is able to seamlessly track its finished goods across halls from indoor to outdoor in real-time, allowing for better decision-making and optimization when it comes to transport chains. By using our software, they are able to see exactly where their materials are at all times and make changes accordingly. By revealing bottlenecks through software-based comparisons of KPIs, dwell times, throughput time, stops, malfunctions, delays, process length or the total time required for a complete cycle - productivity in the yard is increased, ensuring reliable production supply and optimized material flow.

INTRANAV.IO offers an intuitive user interface for appropriate user management, efficient fleet utilization, and sustainably improving the value stream and the supply chain. The real-time digital twin ensures that the construction equipment manufacturer is optimally prepared for future logistical challenges.

The construction equipment manufacturer can reduce its search efforts through virtualization and scannerless recording of all nodes in the yards. This will significantly improve material and production flow by punctual delivery from the yard. By tracking individual assets, personnel can head for finished and semi-finished products in buffer zones on a direct route and manually navigate to the destination, avoiding detours and long walking distances in the yard. Working time can now be used for value-adding activities. Process prioritization enables time-efficient work and transport handling. This will result in increased productivity and profitability for the company.

Automated alerts help factories avoid wasting resources due to incorrect allocation, as well as material wastage from "forgotten" products. Analysis tools help identify bottlenecks and time-delaying processes through systemic key performance indicator (KPI) reconciliations, reducing lead times in the yards and production. The outbound process is simplified and made more secure by automation steps, eliminating the need for manual write-offs. Seamless invoice issuance is triggered when the vehicle leaves the plant, and customers and staff are informed via alerts. This allows everyone to stay updated on the status of the vehicle and avoid any surprises or delays. Overall, automated alerts and analysis tools help streamline factory production processes, saving time and resources.