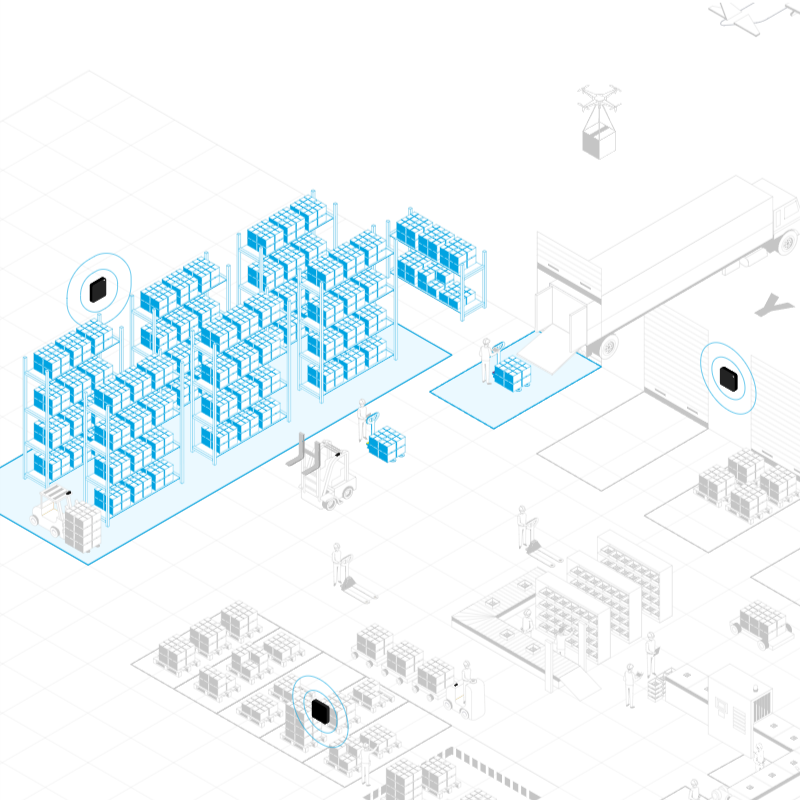

Meet the award-winning Inpixon RTLS platform, providing real-time positioning of whatever it is you need to track in order to achieve improved operational efficiencies, reduced costs, and enhanced worker safety. Automate and streamline processes to gain actionable insights for strategic business decisions while enhancing overall equipment effectiveness in manufacturing and intralogistics. The technology-agnostic platform seamlessly integrates positioning and identification data from various RTLS technologies and other sources (IoT, etc.) with ERP, MES, WMS, and other systems.

Open Architecture

Multi-RF Support

Location as a Service

Real-Time Location Tracking

Instantly locate and monitor the real-time movements of whatever you want to track

Digital Twins & Live Maps

Visualize location data of physical objects or processes, indoor and outdoor

RTLS Device Management

Efficiently manage and configure all RTLS devices for optimal performance

Geofences

Define geographical zones to trigger actions or notifications upon entry or exit

Alerts

Receive real-time notifications based on predefined events or conditions

Asset Management

Control, organize, and configure your specific assets

Automation Trigger

Enable automated actions based on defined rules and events

System & User Management

Administer the RTLS system and customize user rights for optimal usage

Experience hassle-free RTLS deployments with our subscription model – all-inclusive service, regular maintenance, and ongoing support, all covered by a straightforward recurring fee.

.gif?width=281&height=354&name=cropped-animation%20(1).gif)

Pay-as-you-go subscription fee results in lower upfront costs!

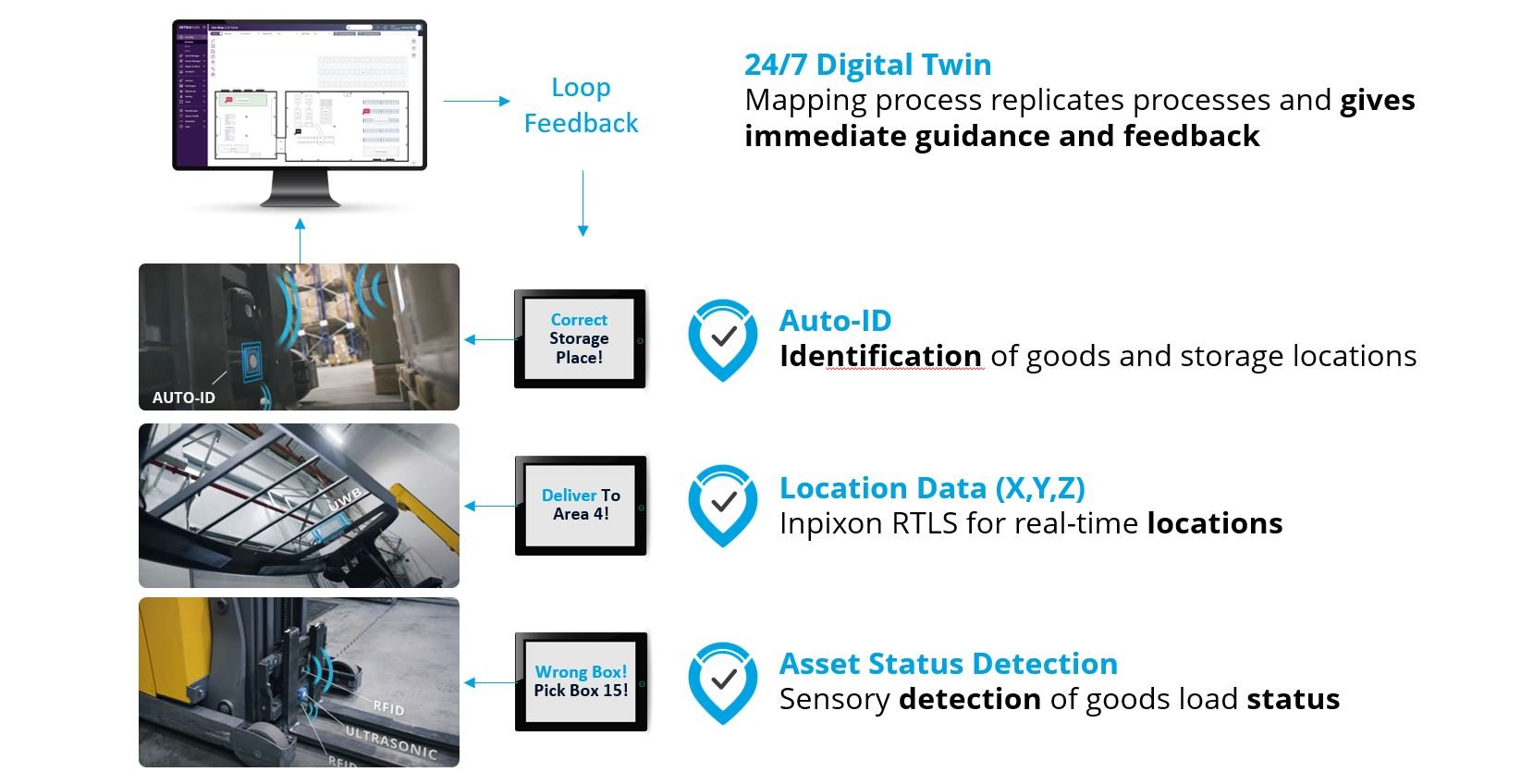

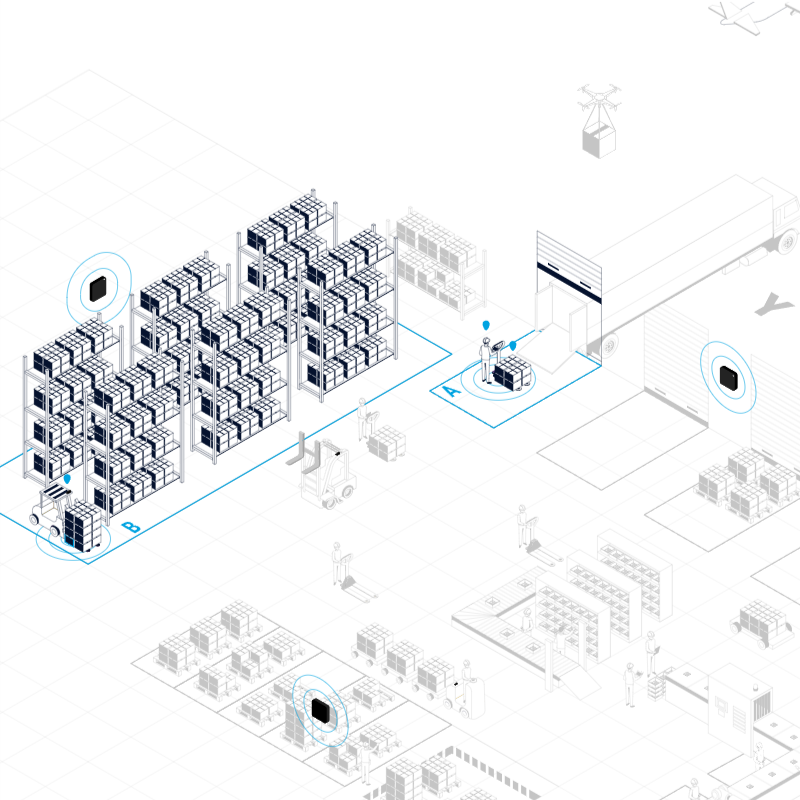

The Warehouse module simplifies and accelerates warehouse management through automatic goods receipt and issue recording without the use of scanners for forklifts. This allows for immediate entries in WMS and ERP, along with automatic assignment of transport orders to the fleet. Precise guidance to shelves and the creation of a digital twin of the inventory further streamline processes. Real-time tracking of forklifts and goods, coupled with automated singulation processes, ensure optimal warehouse management. The closed-loop feedback in the Digital Twin realm provides comprehensive tracking 24/7, enabling the identification of goods and storage locations, as well as real-time monitoring of load status.

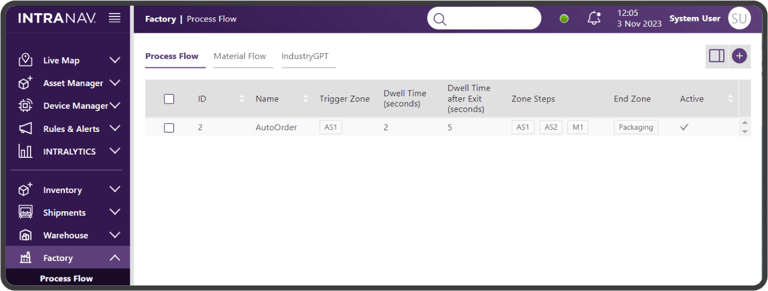

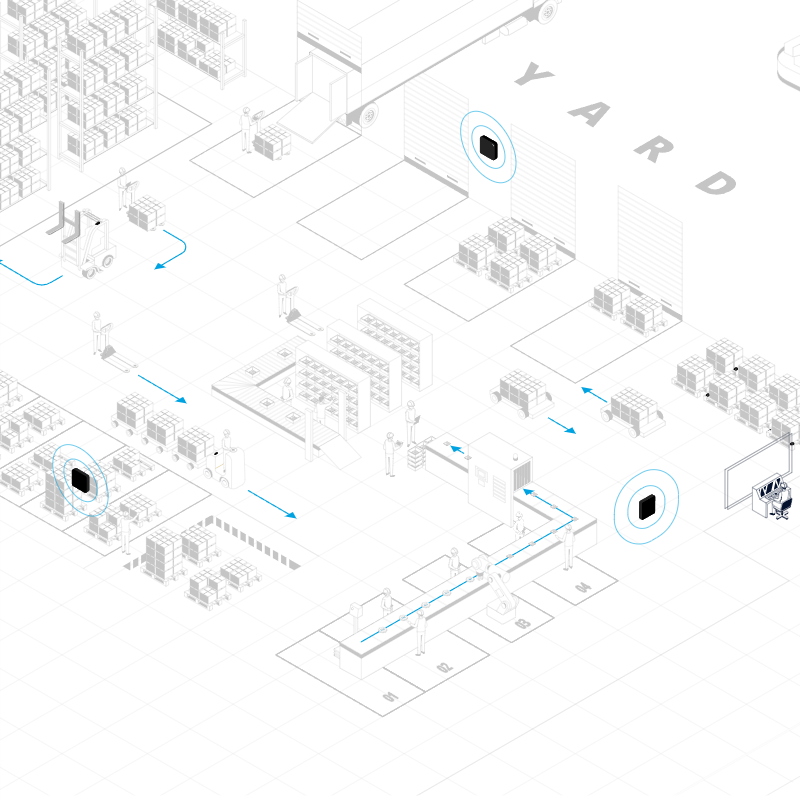

The Factory — Process Flow module records and monitors workflows in production environments using precise time stamps and zones. It provides a structured representation of production processes to identify and intervene in case of bottlenecks and idle times.

Increase transparency across all production processes to gain a comprehensive overview of actions and dependencies. This increased transparency enables proactive measures for a seamless and efficient production cycle.

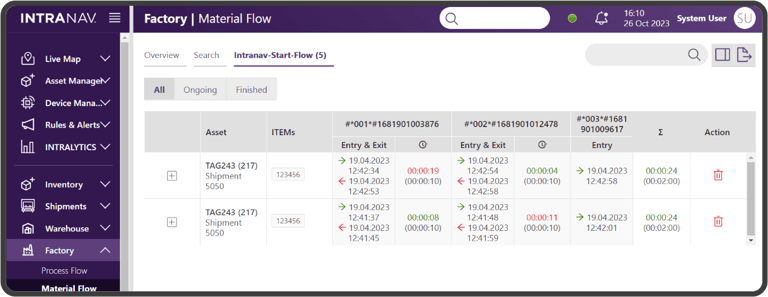

The Factory — Material Flow module meticulously manages material entry and exit points, providing precise dwell time calculations for accurate control and optimization. It offers real-time location data for materials and transport flows, ensuring immediate visibility. Timestamp precision, recorded to the second for each entry and exit, guarantees a detailed dataset. Dwell time calculation adds insight, empowering decision-makers to identify optimization opportunities and enhance efficiency. The 'End Status' feature defines total cycle time, enabling manufacturers to identify bottlenecks and optimize workflow.

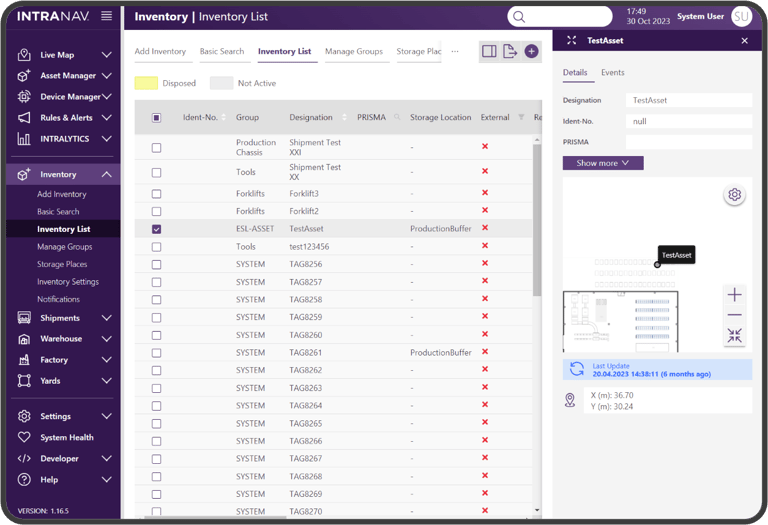

The Equipment manager module enables streamlined inventory management and real-time localization, eliminating tedious searches for components, devices, carriers and tools. The Inventory Archiving & Capture System ensures fast and accurate localization, seamlessly integrating new objects.

The module maps the location data of objects as a "digital twin" in a live map and database, providing real-time visibility that reduces search times and increases efficiency. It improves management, facilitates the movement of groups of objects through search and filter functions and triggers zone-based alerts for seamless integration with third-party systems, reducing errors and enabling proactive action.

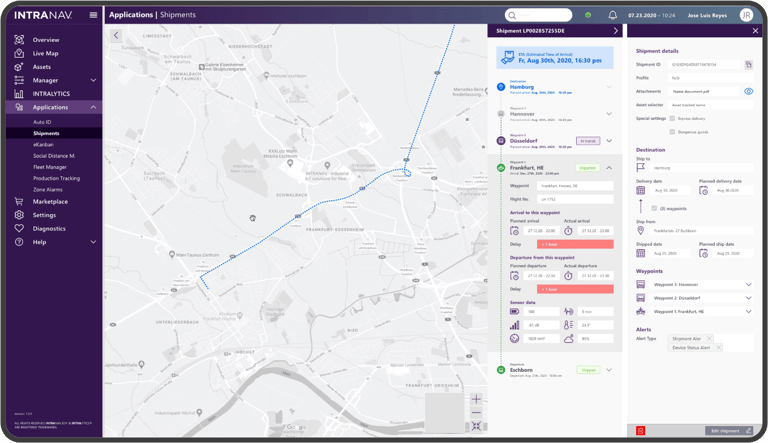

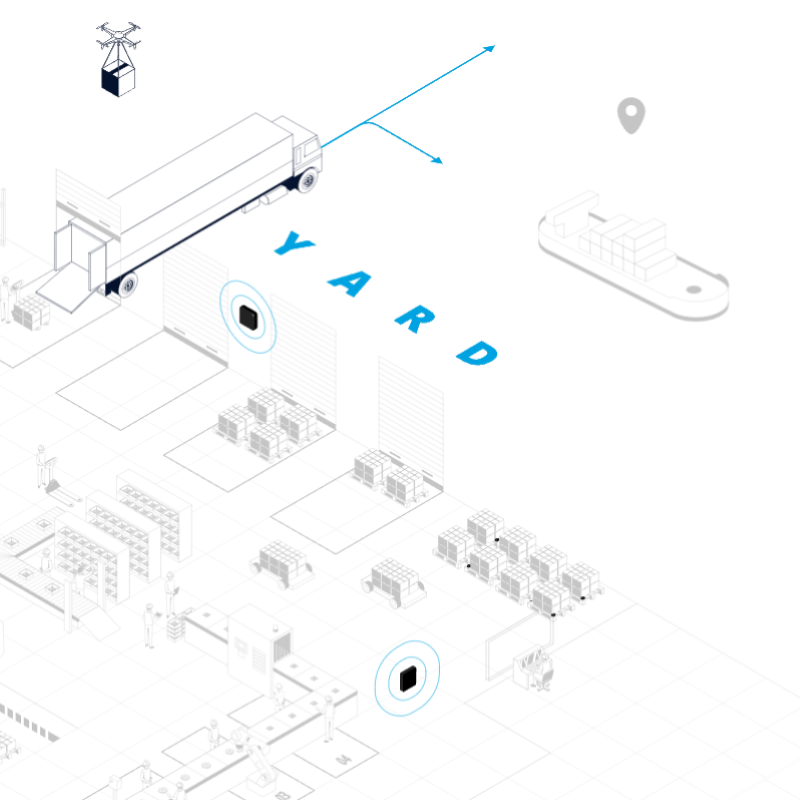

The Shipments module ensures global supply chain visibility by creating a digital twin of shipments and cargo transportation. Tracking all transport destinations, including planned stops, it calculates estimated time of arrival (ETA) based on external data. The system allows input of specific delivery IDs, logistics service provider IDs, and additional information fields. The overview displays all shipments and their statuses, collaborating seamlessly with GPS or third-party devices for continuous monitoring and swift action on delays. Customizable and integrable with third-party providers, it offers real-time alerts for deviations in sensitive goods' conditions and detailed tracking history for in-depth analysis.

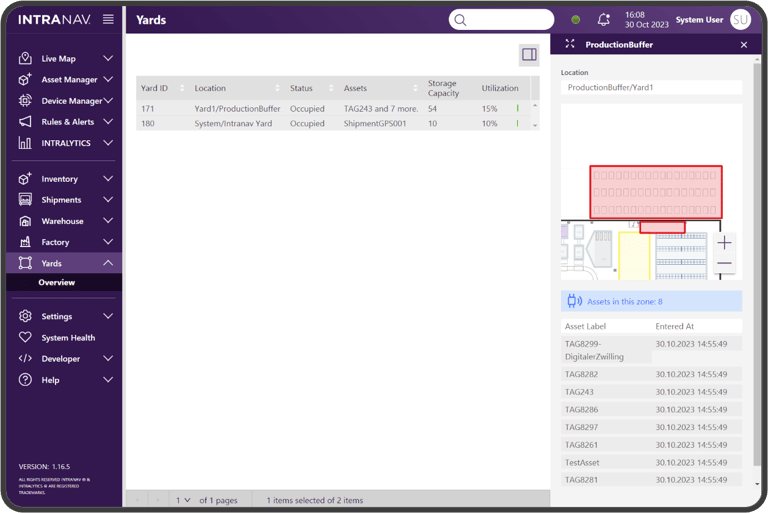

The Yard Module optimizes capacity, reduces search times, and introduces automated workflows for efficient yard operations. Offering real-time visibility and process optimization, it efficiently manages multiple storage areas, monitors occupancy, and minimizes errors through alerts for smooth operations.

The Yard Manager facilitates outdoor storage space management, utilizing GPS tracking devices, CSS-based RTLS, or third-party data sources for visualizing capacity utilization and reducing search times. Users can add multiple storage locations, enhancing transparency and providing a comprehensive overview.

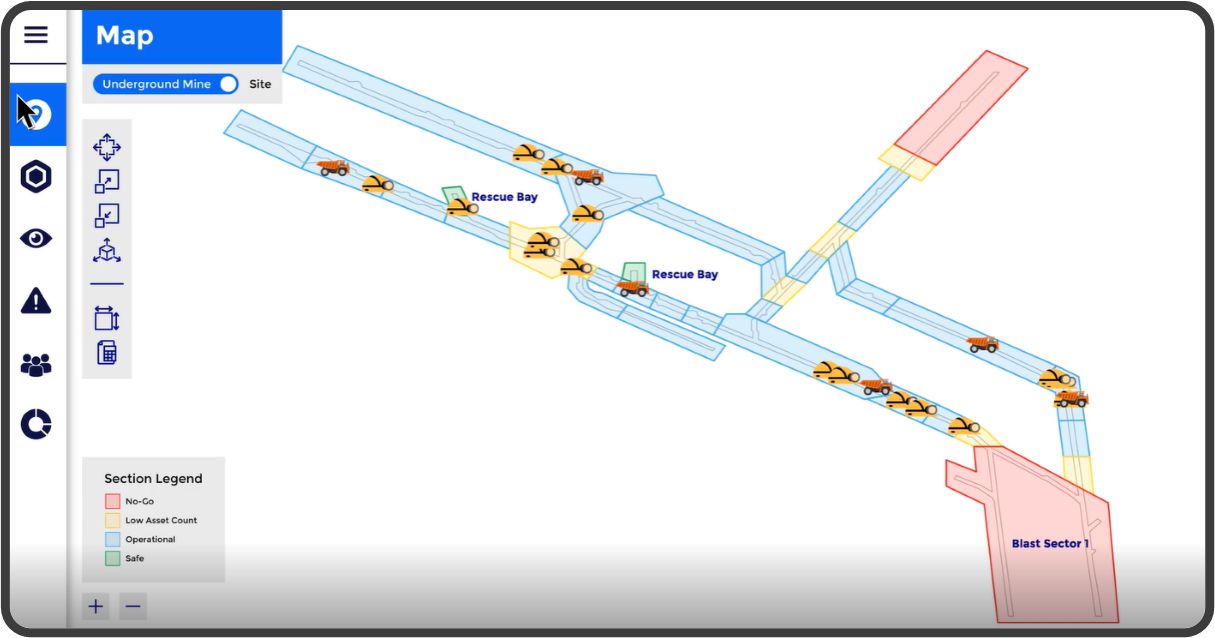

The Smart Mine 4.0 module ensures real-time monitoring of personnel movements and activities, promoting a safer working environment with a collision avoidance feature. It monitors mining workforce productivity, avoids duplication, and aids in effective planning, supporting proactive equipment maintenance and remote operations. The module addresses efficiency, logistics, and compliance through features like traffic control, inventory alerts, and equipment failure notifications. It reduces search times, optimizes routes, and enables rapid emergency response, enhancing safety with geofencing and zone alerts. The heatmap report analyzes patterns for informed decision-making, providing a comprehensive solution for safety, efficiency, and operational excellence in mining environments.

Location data and software digitize the entire inventory, including pallets, crates and bins, creating digital twins that deliver complete transparency and a real-time overview of your inventory.

Achieve automatic goods booking in the ERP/WMS system, the most efficient use of storage and transport routes, and optimized allocation of storage locations.

Automatic identification (AutoID) rationalizes the recording of incoming and outgoing goods, eliminates the need for manual scanning, and automatically posts data into the ERP/WMS. Inpixon enables single-sort bundling and storage of parcels as "virtual pallets" in the ERP/WMS.

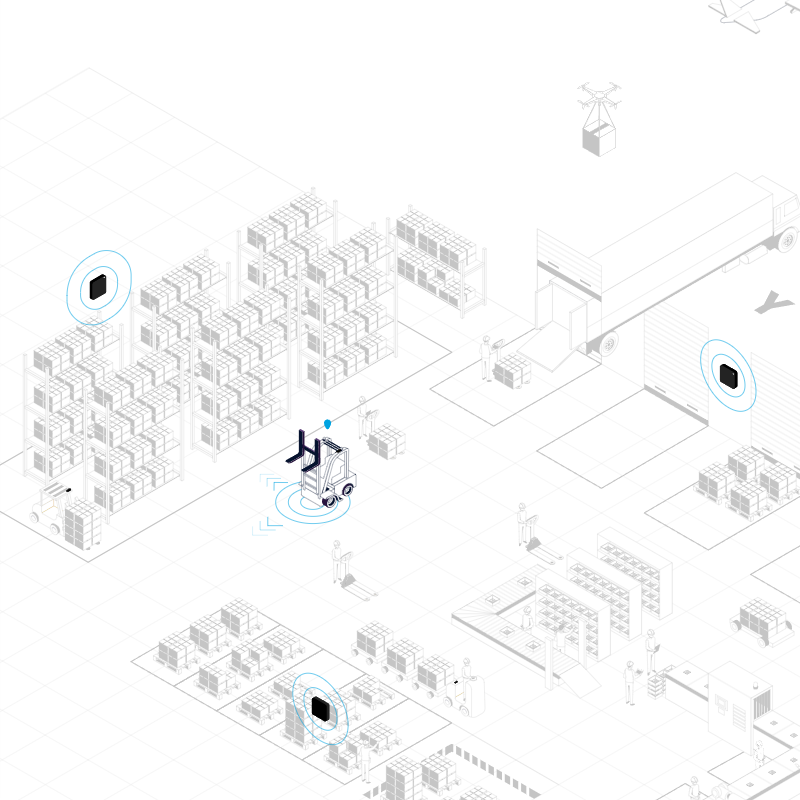

Real-time location data of the transport vehicles allows routes to be optimized and traffic jams and dangerous situations to be proactively avoided. Equipping the forklift with sensors enables the AutoID detection of goods, which leads to faster throughput times without the driver having to get off the forklift.

The implementation of a real-time location system (RTLS) offers many advantages for mixed fleets of autonomous guided vehicles (AGV) and manually controlled vehicles. Through precise positioning, RTLS enables optimized route guidance, minimizes travel times and improves energy efficiency. Real-time status monitoring enables effective fleet monitoring and rapid response to events. Automatic vehicle identification supports the accurate detection and tracking of movements in real time. RTLS also helps prevent collisions between different vehicle types and promotes safety in mixed environments.

Inpixon offers collision avoidance systems for people and industrial vehicles based on location and sensor information. In the event of an potential collision, the system automatically triggers acoustic and visual warning signals. At critical distances, the vehicle automatically slows down or comes to a complete standstill.

Other safety functions in industrial plants include warning signals when safety limits are exceeded and the detection of unauthorized personnel in sensitive areas.

End-to-end tracking of production orders and real-time digital updates throughout the production process enables efficient plant control. The precise position tracking of load carriers and production goods, combined with automatic cycle feedback in the ERP/MES, supports synchronized pre-assembly and main assembly and reduces idle times. The reduction in manual scans saves valuable time per sequence. The automatic component check based on location information and comparison with the MES minimizes errors in the assembly process. This leads to an increase in overall equipment effectiveness (OOE), which in turn means you can achieve a higher total quantity of goods produced each year.

Real-time data provides production and warehouse managers with enhanced process visibility. Inpixon accurately records and monitors processes in both the production and warehouse environments, enabling real-time analyses with time and zone precision. The structured display of assembly and material flow processes in Inpixon RTLS facilitates the immediate identification of bottlenecks and idle times, allowing for targeted interventions and a comprehensive overview of actions and dependencies.

Real-time localization for fast positioning, process control, safeguarding, and efficient equipment utilization (OEE). Also, obtain availability of special tools as well as predictive maintenance needs through automated messages.

View real-time location information of assets, vehicles and people in the yard as a digitized parking lot. Vehicles can be navigated to the correct dock or gate manually or by linking to transport guiding systems. Get control security during the loading of vehicles and automatic alerts in case of delays in the process.

Achieve comprehensive global visibility of your supply chain through real-time tracking of freight shipments, including calculated estimated time of arrival (ETA). Continuous monitoring enables immediate action in the event of delays. Precisely monitor the condition of goods and deliveries by measuring temperature, humidity and vibrations. Control container fleet utilization, ensure route compliance, and take action on route anomalies to reduce loss and prevent theft.

The Inpixon RTLS platform stands out for its strong emphasis on interoperability, seamlessly integrating with critical systems like SAP, ERP, MES, and WMS. With open APIs, it ensures easy access to RTLS functionalities, facilitating smooth integration with various applications. Standardized protocols and support for industry standards and RTLS norms promote efficient collaboration across diverse devices and systems. The platform's compatibility extends to IoT standards, data formats, cloud integration, and PLCs, providing a holistic and synchronized approach to industrial connectivity and automation.

IntegrationsSmart Manufacturing

Automated Warehouse Operations

.png?width=250&height=250&name=Untitled%20design%20(9).png)

Quality & Process Control

-1.png?width=250&height=250&name=Untitled%20design%20(8)-1.png)

Security & Safety

Get a consultation to discover how to automate your processes with RTLS!

RTLS enables real-time monitoring of incoming goods and automation of goods receipt tracking. It offers instant visibility into expected deliveries, AutoID registration, and guides employees with digital instructions for efficient sorting and palletization. Additionally, it automates warehouse transport job creation, seamlessly assigning tasks to forklift operators.

Faster Goods Receipt

RTLS streamlines warehouse management, eliminating manual scanning with automated goods identification upon receipt. Digital notifications alert forklift drivers upon pallet loading, providing precise destination details within the warehouse. Additionally, it automates inventory posting in the warehouse management system (WMS) using AutoID technology.

Faster Goods Storage

Optimize your outbound processes by accelerating picking, automating outgoing goods posting in the warehouse management system (WMS) through AutoID, and triggering label generation with geofencing. Enhance your experience with seamless invoicing directly at the point of goods dispatch, ensuring a smoother workflow and improved efficiency.

Faster Outbound Processes

askPixi™ is a conversational agentic AI that combines real-time location data with your ERP, MES, and planning systems. It predicts disruptions, explains root causes, and automatically triggers corrective actions.

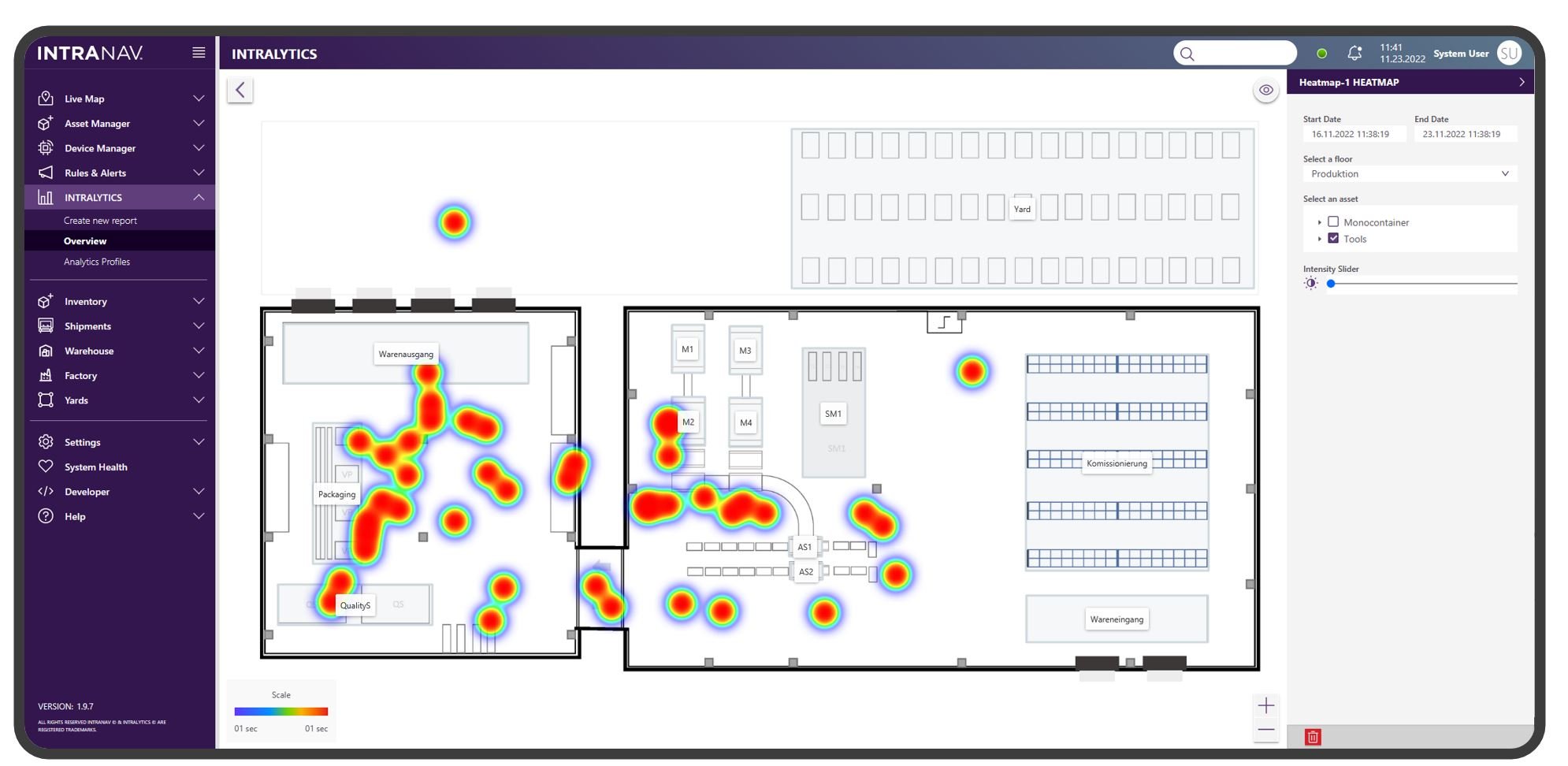

Heatmaps offer detailed analysis and visualization of temporal frequencies in transport and material flows, identifying high-traffic points and durations of stay. They pinpoint congestion, waiting, and inspection areas for proactive issue resolution. By recognizing trends and anomalies, businesses can efficiently allocate resources, reduce congestion, and optimize workflow. Heatmaps contribute to overall efficiency by providing insights into waiting times and enabling proactive issue resolution for a streamlined operational environment.

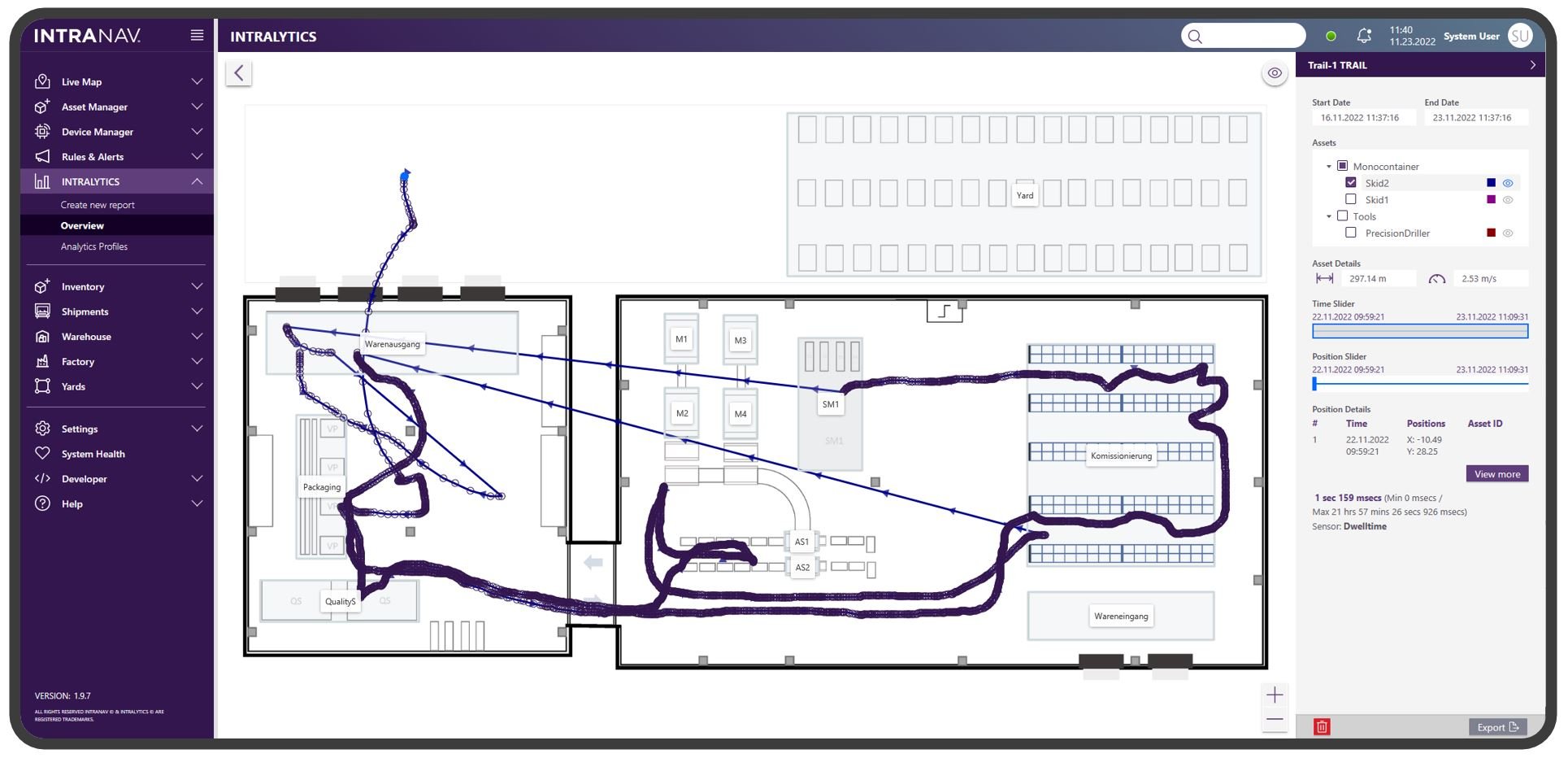

Trails provide real-time insights into asset and vehicle movements, optimize production layouts and uncover inefficiencies. This enables the evaluation of fleet efficiency, route compliance and the adequacy of workplace organization. Pathways are critical to improving operational dynamics and eliminating waste in workflows.

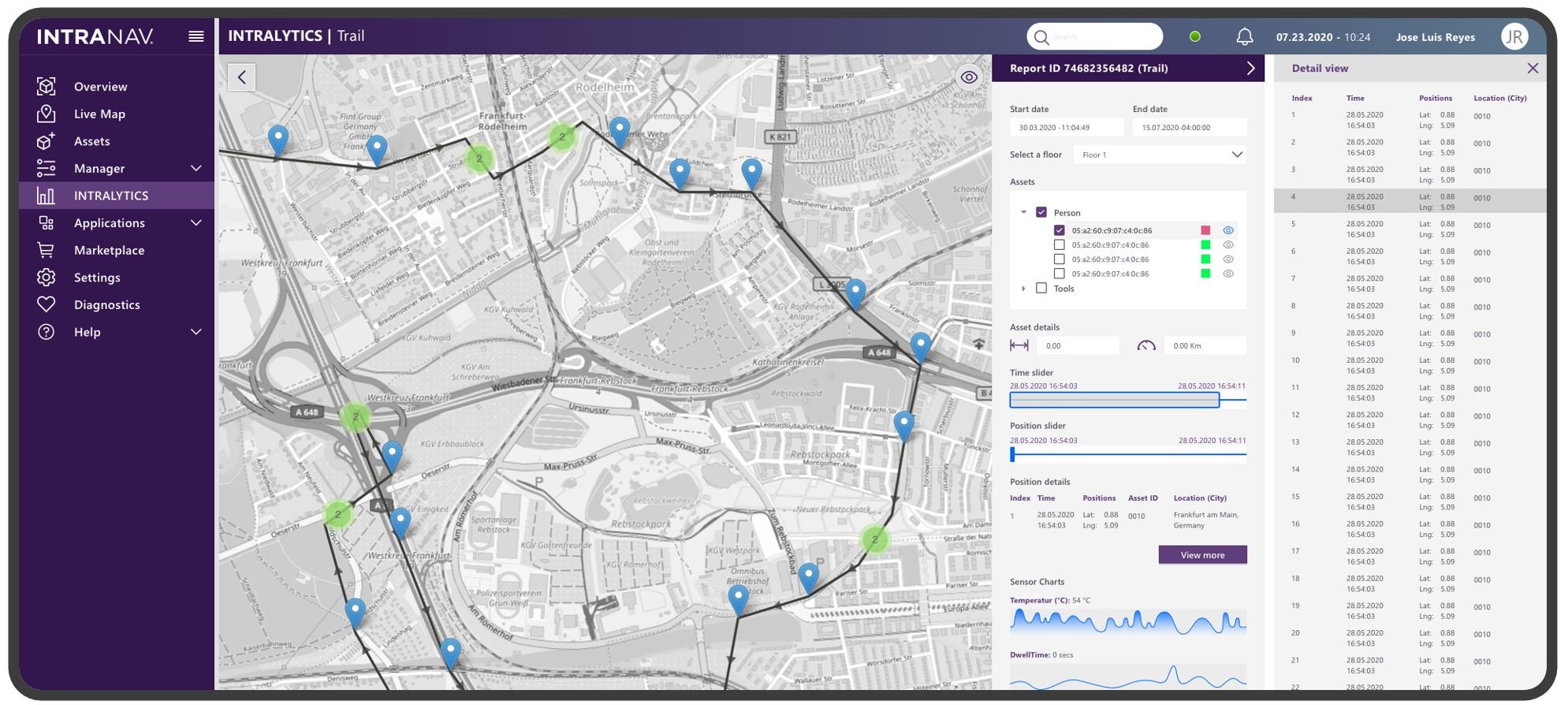

Outdoor Trails provide a comprehensive solution for supply chain optimization. They enable companies to track vehicle and container operations, precisely control costs for fuel, maintenance, and labor. This proactive approach includes identifying potential risks and insecure routes to enhance safety and reliability.

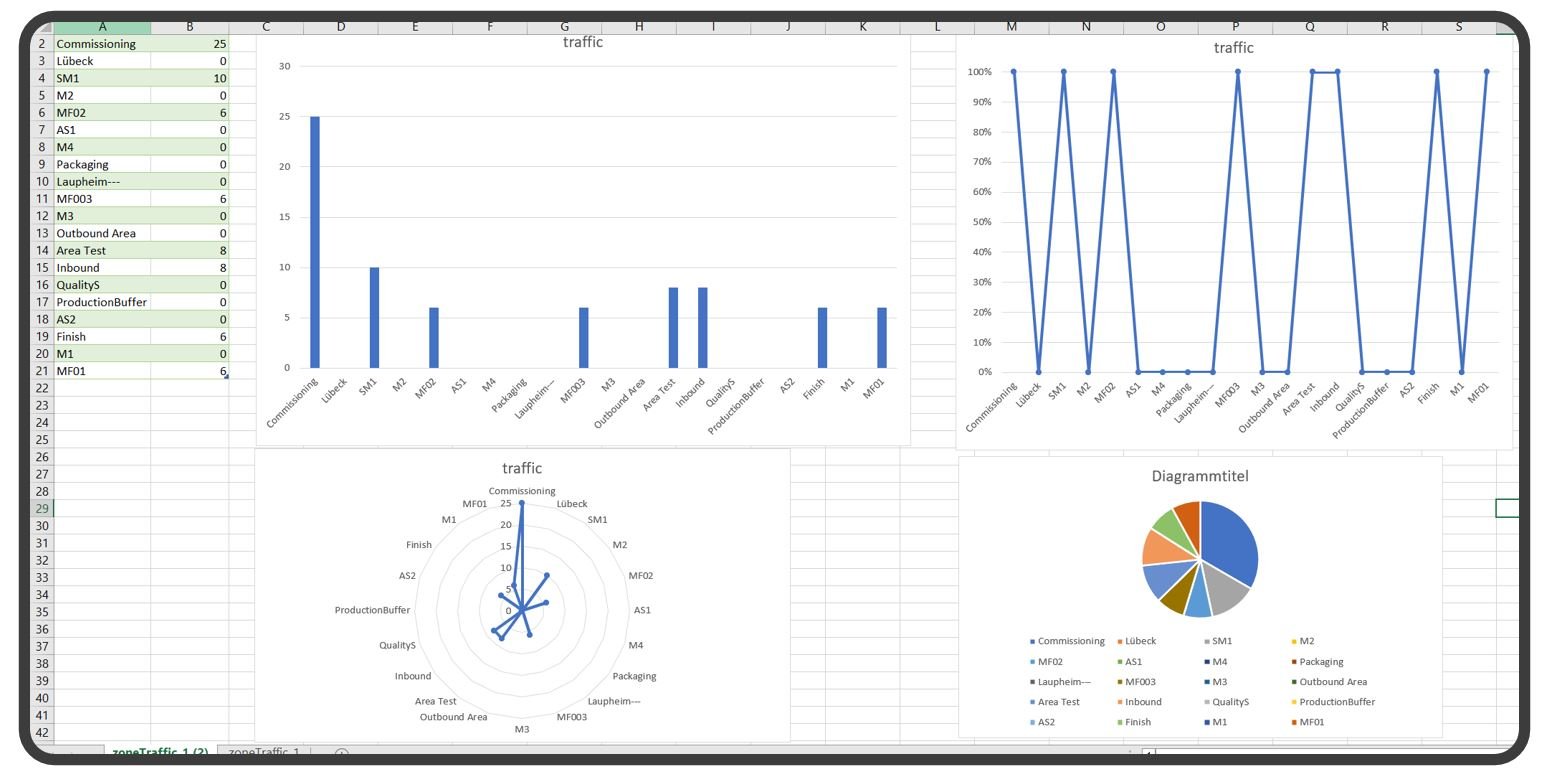

Zone Dwell Time Analysis provides a detailed overview of object performance in specific zones, displaying average dwell times and identifying bottlenecks. It aids in prioritization, addressing high-dwell zones and enhancing resource allocation.