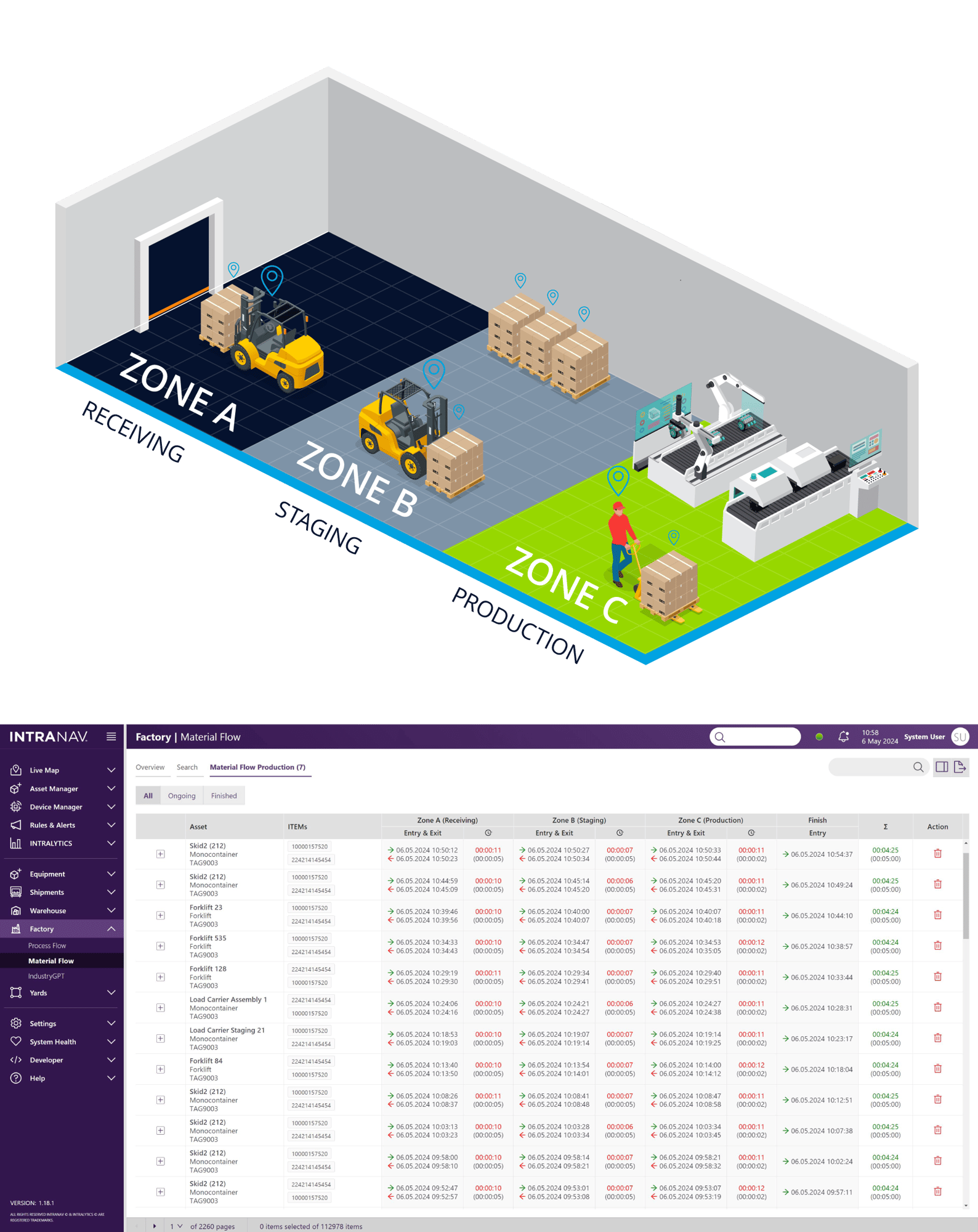

Our Real-Time Tracking and Analysis system, powered by RTLS (Real-Time Location System) technology and our comprehensive RTLS platform, transforms how businesses monitor and manage their material flow.

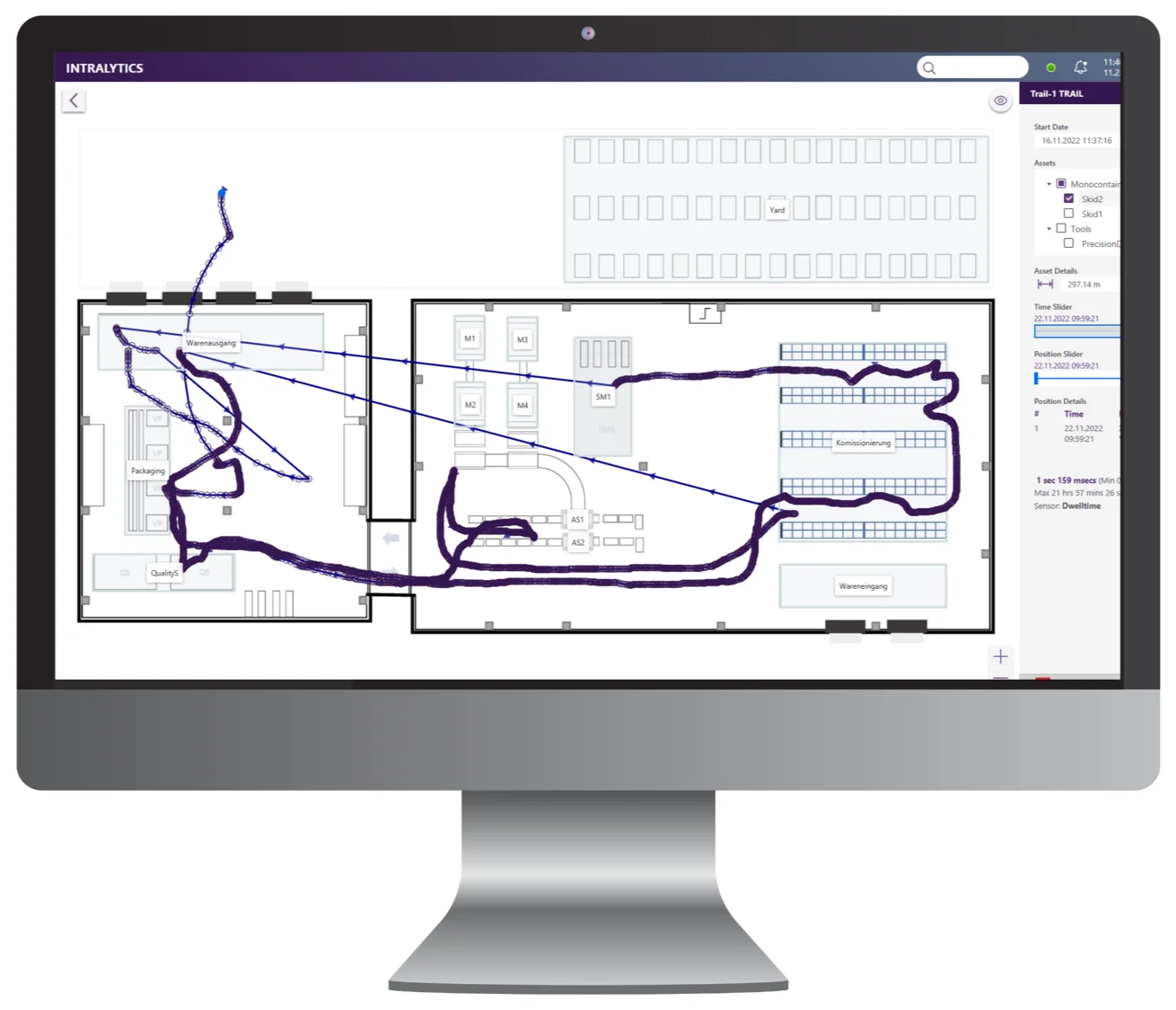

With our solution, you gain real-time visibility into the movement of materials throughout your facility or supply chain. Every item is tagged and tracked with precision, allowing you to monitor its journey from point of origin to destination instantaneously.

But it's not just about tracking. Our RTLS platform offers powerful analytics capabilities, providing actionable insights into material flow patterns, dwell times, bottlenecks, and potential areas for improvement. With this data-driven approach, you can streamline processes, optimize resource allocation, and ultimately enhance productivity and profitability.

Moreover, our solution seamlessly integrates data with other systems, ensuring that information flows effortlessly across your organization. Whether it's your ERP system, WMS , or MES, our RTLS platform enables cohesive data exchange, facilitating holistic decision-making and operational synergy.

-3.png?length=1000&name=Inpixon%20LinkedIn%20Banner%20August%202025%20(2)-3.png)

-1.png?width=155&height=96&name=Mask%20group%20(4)-1.png)