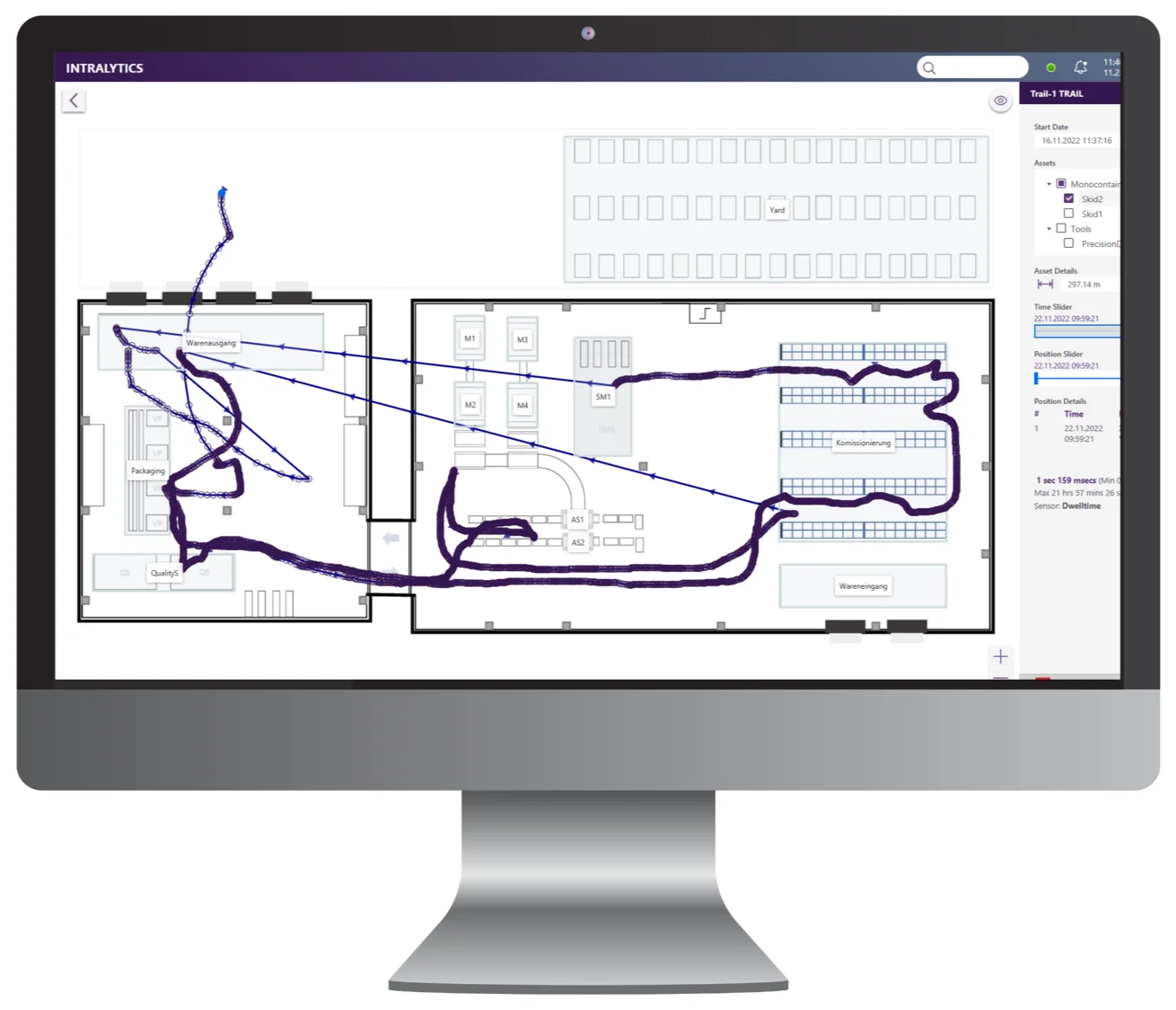

Real-time Location Systems (RTLS) play a crucial role in optimizing production processes in the modern Smart Factory. By integrating material flow, information flow, automation, and process optimization with real-time location tracking, RTLS provides visibility and transparency in manufacturing. RTLS enables real-time tracking of equipment locations and progress, allowing managers to identify resource misallocations and improvement areas. With fast data capture and analysis, managers can deploy resources rapidly and prevent costly errors. Automated asset tracking reduces the need for manual data entry, lowering labor costs and contributing to optimizing production processes. By using RTLS in production tracking, manufacturing companies can increase efficiency, flexibility, and transparency while improving quality standards and OEE. With a high ROI, RTLS is the perfect solution to achieve a highly efficient, digitally connected, flexible, transparent shop floor.

-3.png?length=1000&name=Inpixon%20LinkedIn%20Banner%20August%202025%20(2)-3.png)