SUCCESS STORY

Production process and transport optimization through real-time material flow tracking and management

Read More Download PDFA leading international production control and automation technology company and market leader in technical education and training for industrial qualification solutions, this company’s portfolio includes pneumatic and electric drive technology for factory and process automation.

Throughout our client’s supply chain, finished goods move within and across factories at 3 locations. Inpixon’s INTRANAV IoT platform’s role is to transparently display real-time material flow processes by digitizing the live movements and inventories of finished goods, as well as the load carriers used to transport them, to reduce lengthy and inefficient search efforts and status determination in the future. Simultaneously, processes such as manual scanning needed to be reduced to optimize working times and avoid booking errors.

The transition to Production 4.0 also requires digital production orders and accompanying documents instead of paper consignment bills. These are impractical to handle and, if misplaced, critical information regarding the finished product is lost as well. For that reason, the company required a paperless solution in order to be able to retrieve goods and their accompanying documents electronically and post them automatically into their SAP system.

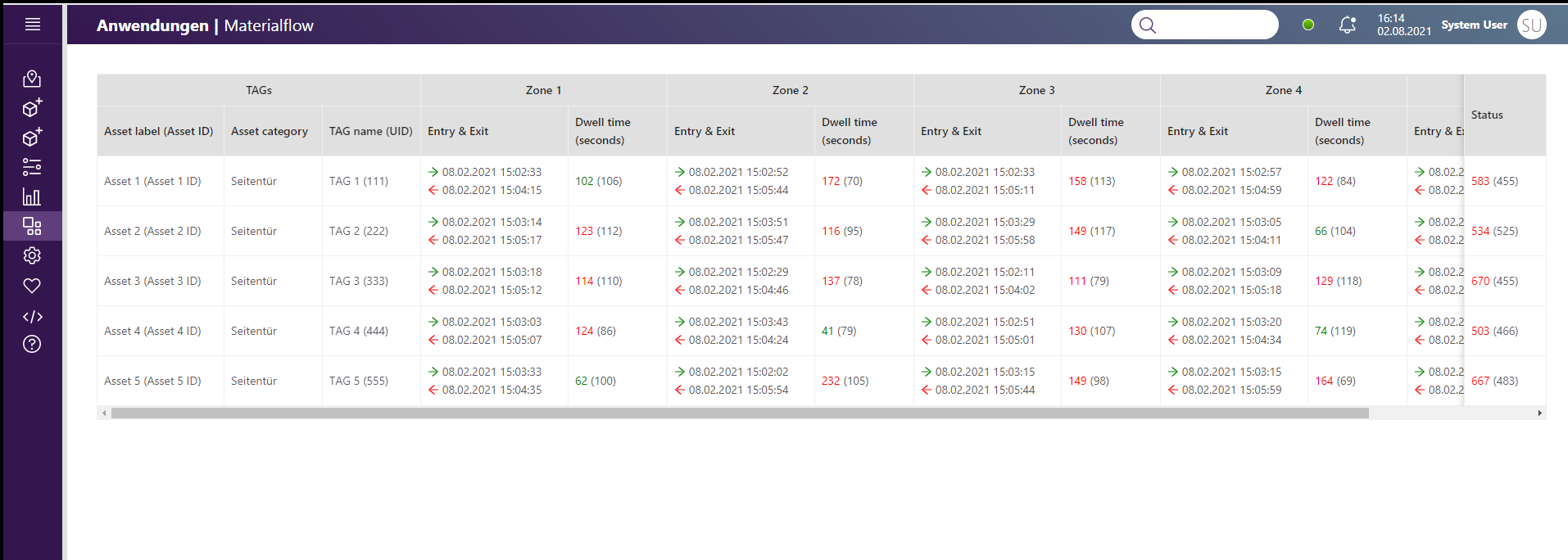

Another important requirement was the ability for the client to view and continuously analyze the throughput times of each individual material handling station. The data obtained through real-time location tracking via INTRANAV’s solution is then used to analyze the flow of goods and status of values through material flow reporting to optimize material lead times and supply processes. Overall, this brings significant quality improvements in the way materials are managed. The IoT sensor-based solution will track packages from their starting point to their destination point, as well as through all intervening nodes (storage levels/buffers) in real time.

Reduce Search Times Through Real-Time Material Flow Location Tracking

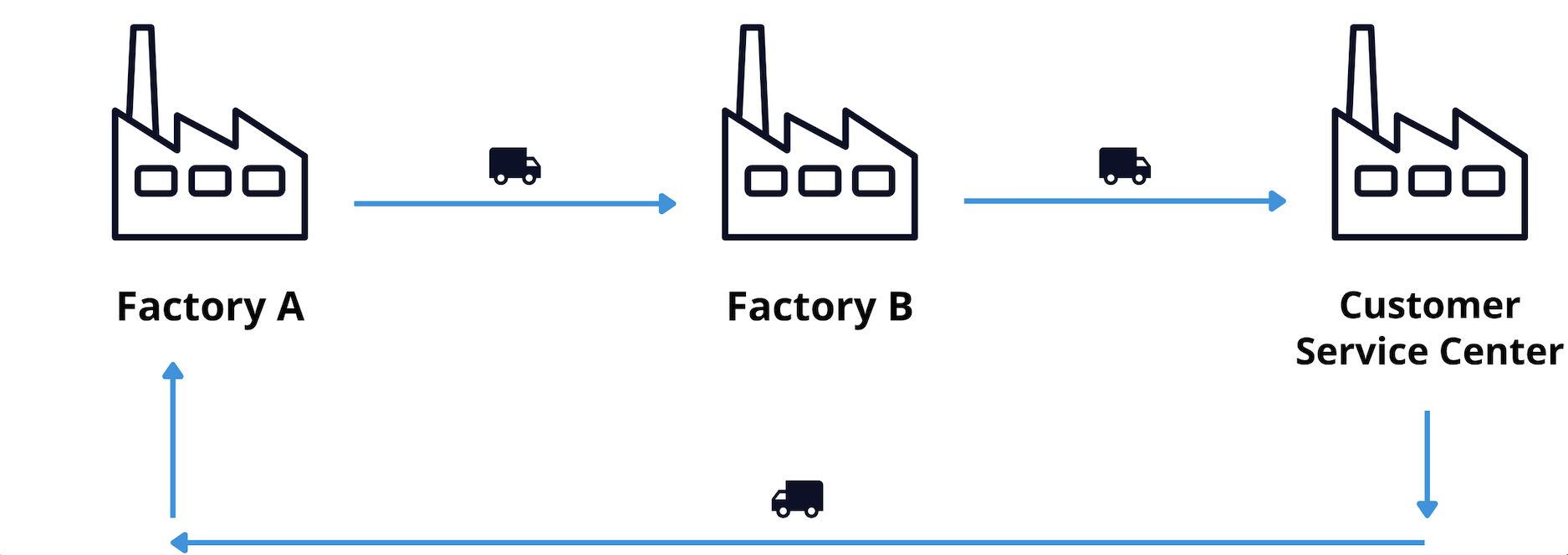

All material flow deliveries from the factories to the Customer Service Center are tracked indoors. Planned deployment expansions will extend this real-time tracking into outdoor areas in the future.

Material Flow Analysis

The wait time and throughput time of all stations passed through can be evaluated for goods via an app and are used for cycle time/process optimization.

Replacing Scanning Activities with Automated Capturing in Internal Transports

Packages must be recorded per workstation (storage level, buffer) for ease of tracking and maintenance via Auto-ID in the INTRANAV.IO and SAP system.

Paperless Logistics

Production orders are associated with INTRANAV.RTLS tags in the INTRANAV.IO and SAP backend by scanning each workstation to enable seamless order management.

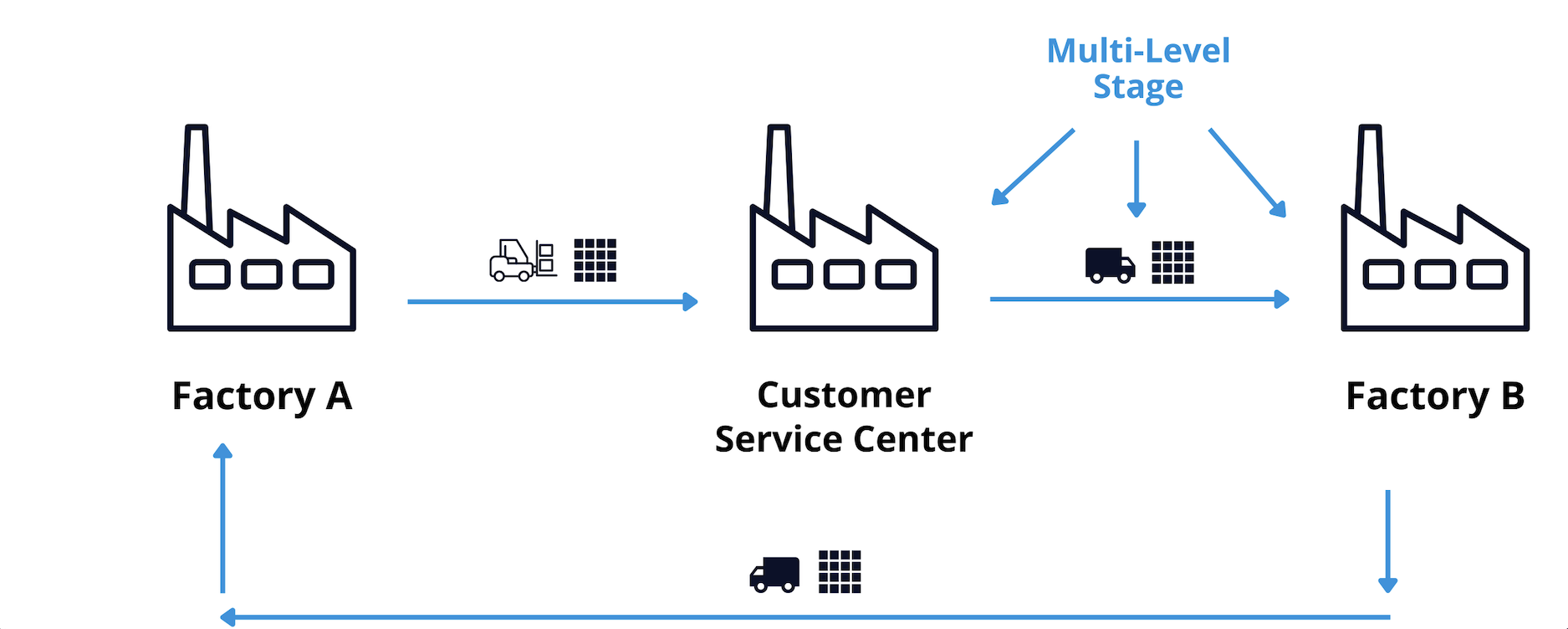

The client’s primary goal is automated internal material flow as well as the replacement of individual scanning activities in internal transport. Inpixon identified two use case solutions within the production and logistics area so that finished products of the automation engineer are moved and tracked within 3 locations (Factory A, Factory B and Customer Service Center), with traceability for open and closed transports:

Packaged and finished goods are tracked from Factory A to the external warehouse in Factory B. A partial quantity of the goods are then unloaded at one of the company’s customer service centers. The packed bulk goods are wooden crates that are not palletized and, in many cases, exceed the dimensions of the Euro pallet.

Packed cylinders are transported from production to the Customer Service Center via internal transport, where they are packed and buffered on the loading ramps. Later, they are picked up by the transport service provider and taken to the external warehouse in Factory B. Buffering takes place in the wire grid boxes in which the packages are located. Approximately 20-30 packed cylinders are transported per grid box.

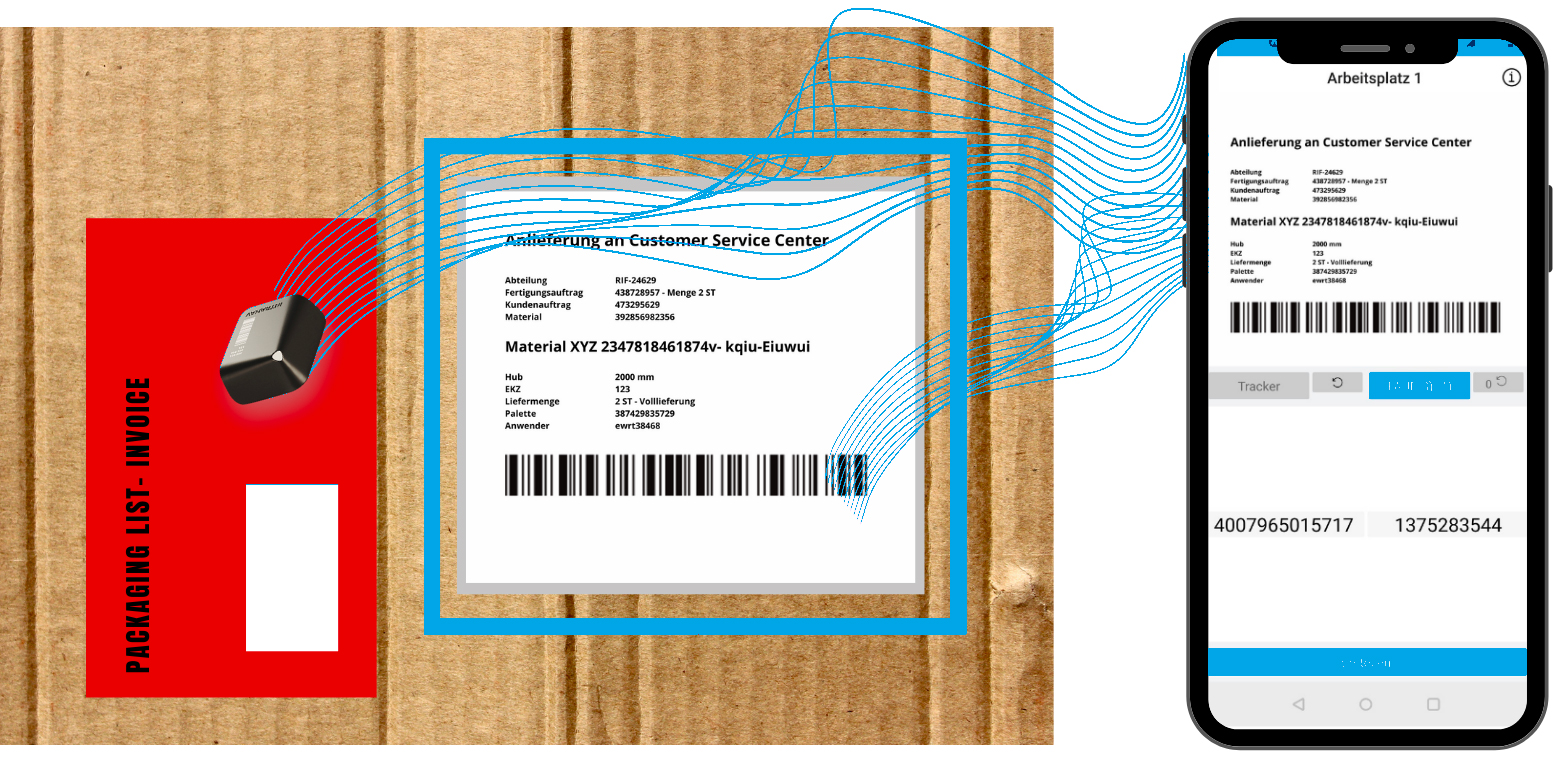

The IoT sensor-based INTRANAV RTLS solution tracks the packages indoors and in real-time from their starting point to their destination point (Factory A – Factory B – Customer Service Center) as well as via all intermediate nodes (warehouse levels/buffers.) For this purpose, tracking tags are attached at the starting point and associated with the respective production order via INTRANAV.APP barcode scan, `i.e. connected in the backend of the INTRANAV.IO and SAP system.

Packages are now automatically registered at all nodes (buffer area, shipping area, etc.) when entering the workstation via a geofence (virtual zone), eliminating the need for manual scanning.

At the respective material flow stations, additional production information (production order numbers) is stored on the individual packages. The packages have a unique ID (2D barcode) and are associated with the corresponding information by scanning the tag, which also has a unique ID, at the respective work/buffer stations via mobile device in INTRANAV.IO and SAP. For this purpose, a mobile device equipped with the new INTRANAV.APP barcode scan is stored at each workstation.

With the INTRANAV.APP, employees scan just these numbers, creating a new asset in the INTRANAV.IO platform, which can then be tracked. The app is specifically designed to match barcode information (goods slips, production orders) with tags.

After arrival at the Customer Service Center or Factory B, the goods are taken to two possible zones, depending on the material flow relationship. As soon as the specified zone is reached, the linking of the information to the tag (waybill) is automatically deleted by the Rules feature via a geofence in the INTRANAV.IO system. At this point, the tag is empty and can be rewritten with new information. The empty tag is collected in containers at the corresponding zone and transported back to the starting point, Factory A, at regular intervals.

With the digitized real-time data, our customer now has all historical data on completed transports available in a database/Excel. With the new INTRANAV.APP Material Flow, all individual material flows and material flow relationships can be analyzed in real-time or retrospectively. The app stores the exact timestamp (day/hour: minute: second) of the entry and exit of the respective zone and calculates the dwell time to the second in the respective zone. The end status indicates the throughput time of all zones and intermediate transit times per asset/package/material flow relationship. Material flow throughput lead times and process optimizations are now based on historical data of completed transports, as well as the dwell times of the goods at the passed nodes.

For area detection, INTRANAV equips the tags with the latest Wirepas Massive hardware stack technology, which enables easy installation, long battery life, and the lowest infrastructure cost for coverage (0.05ct per m2). The Wirepas Mesh delivers standardized data transmission, high scalability, and 99% battery operation of the RTLS tags.

With Inpixon’s INTRANAV RTLS solutions, the digital, cross-location recording of the flow of goods and values within production and logistics was realized. The INTRANAV system is used for tracking various material flow relationships and is scalable to support further use cases and additional real-time location software and hardware. The production efficiency and quality improvements achieved by our customer are measurable in order of magnitude and therefore immediately comparable. The RTLS can be used internally by various departments within our customer’s supply chain, realizing the potential for (real-time) optimization of processes:

Inpixon’s INTRANAV platform offers a highly flexible and cost-effective enterprise solution, ideal for automotive, production, intralogistics and logistics or supply chain RTLS use cases.