SUCCESS STORY

Real-time supply chain visibility for proactive responses to supply chain disruptions

Read More Download PDFA leading international vehicle manufacturer based in Germany, this company is one of the largest premium passenger car and commercial vehicle suppliers worldwide.

This automotive company manages a complex worldwide supply chain network based on a multi-level distribution concept. Global supply chain visibility is a prerequisite for secure, safe and efficient execution of logistics processes. This is especially true in their international shipments for lithium-ion batteries. When in transit, these batteries often need to be shipped in special safety containers, as in many cases, they are declared hazardous goods and subject to strict transport regulations. To ensure safe and reliable transports of these goods, the company needed a global tracking solution to provide real-time transport location and condition monitoring, with features such as sensor-based alerts for deviations from compliance requirements, as well as predictions of arrival times for shipments in transit.

Global Safety Box Tracking & Monitoring

Real-time tracking of current transport location status with hazard monitoring for chemical and battery containers.

Warning System & Control of Transport Conditions

Monitoring of temperature, humidity, and acceleration/shock in the container. Real-time alerts in case of deviation from pre-set limits or process interruptions via SMS and email.

Predictive Time of Arrival

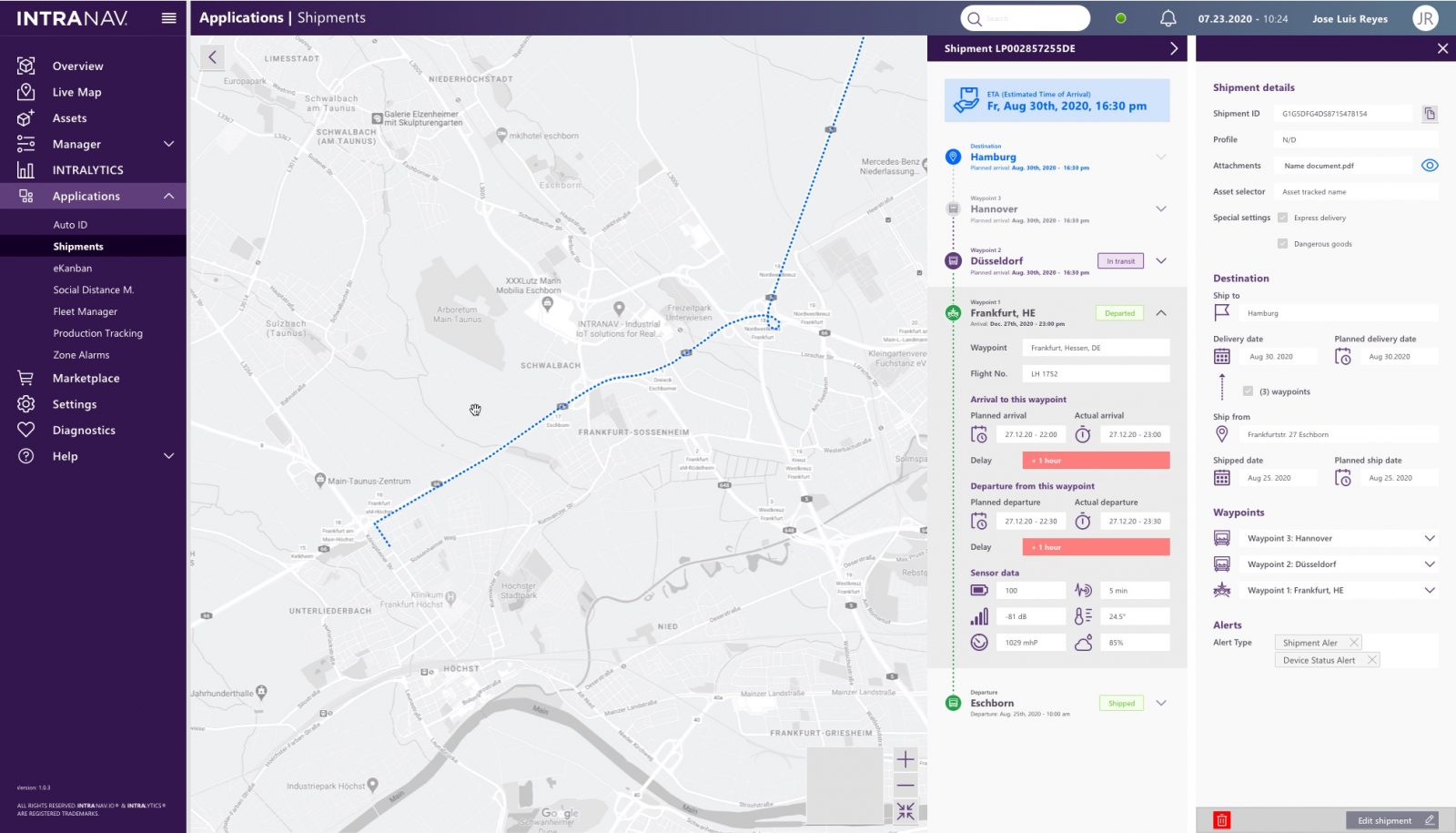

Predictions of arrival times for international shipments.

Theft Protection

Continuous location visibility and alerts to prevent theft and loss of high-value goods.

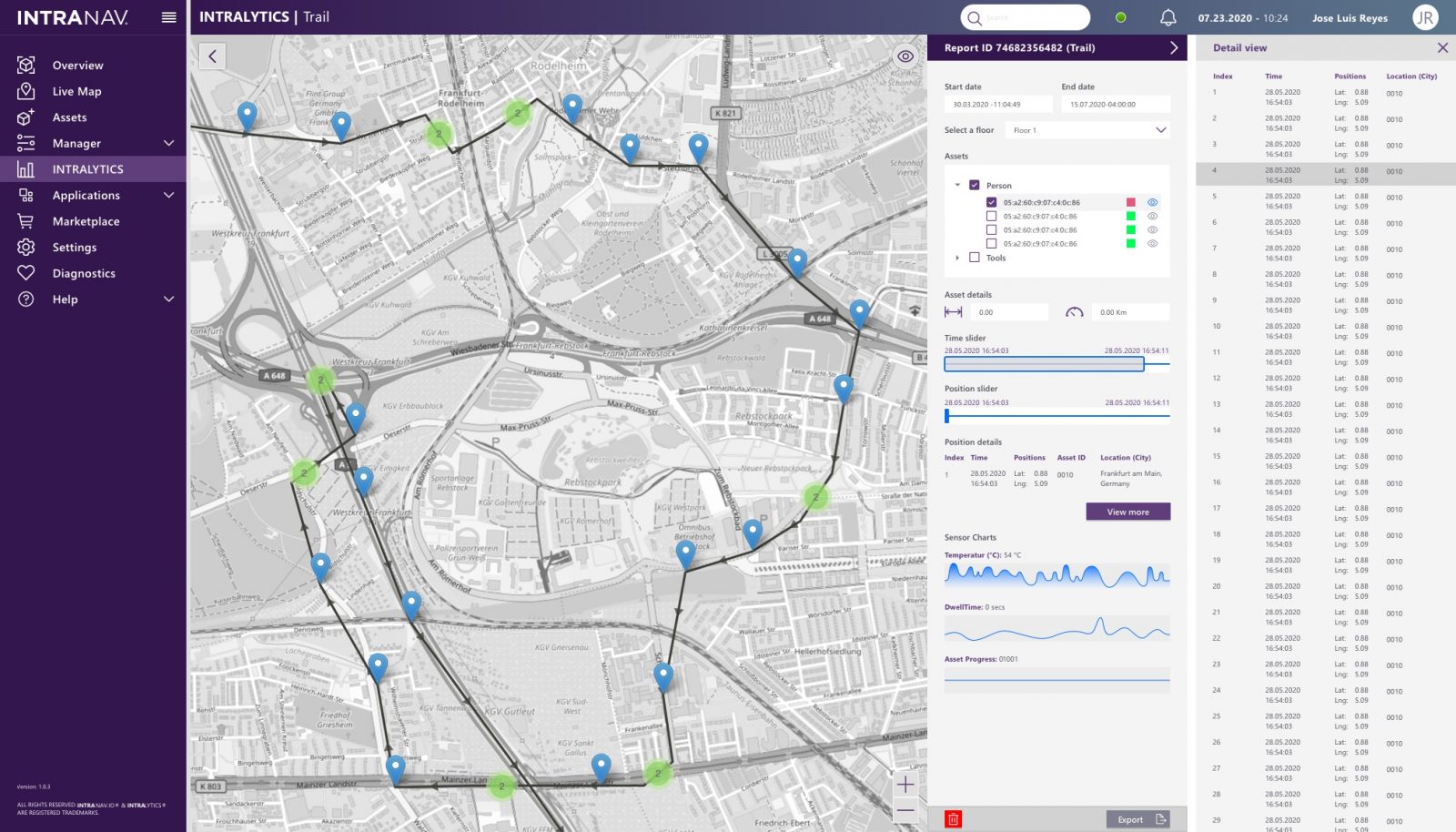

Inpixon’s INTRANAV solution enables the vehicle manufacturer to track over 200 safety containers in real-time and monitor their movements and statuses as a location-aware digital twin.

An external temperature sensor can determine values inside the container, in real-time, increasing process reliability by permanently monitoring the lithium-ion batteries. The INTRANAV Real-Time Location System supports container management by minimizing the risk of temperature damage that could occur during the transport or storage of lithium-ion batteries. If the non-critical temperature range of -40°C to 80°C is exceeded or falls below during transport, a notification is generated to deliver temperature warnings via SMS and email to the appropriate personnel.

If defective or damaged lithium-ion batteries are transported, INTRANAV.IO can be used as an early detection system. By monitoring the inside of the container, the thermal reaction of a battery can be detected and reported with a notification. By detecting the chemical reaction, further safety measures can be initiated. For example, evacuating hall areas or leaving highways during transport before leaking hydrofluoric acid.

To anticipate disruptions and react accordingly, the INTRANAV system is equipped with a predictive time of arrival feature so logistics partners are immediately informed about compliance or delays.

The safety containers that protect these goods are also quite valuable, and GPS positioning not only enables tracking for real-time monitoring of shipment safety and goods’ conditions, but also security in the event of theft or loss.

With Inpixon’s INTRANAV solution, this automotive manufacturer ensures maximum process reliability of container shipping across global supply chain networks. Through sensor data monitoring via INTRANAV.IO, the company evaluates in real-time or via analytics reports whether transport benchmarks such as temperature, humidity, and acceleration (vibration) are being met, or if deviations have occurred. These reports are crucial for insurance claims against supply chain partners because deliveries with breakage or similar circumstances are thus immediately detectable and verifiable.

Through the Shipment Management solution, the company drastically reduced search times through real-time visibility of in transit shipments across their supply chain network. They also experienced a 20% reduction in the amount of lost containers and significantly boosted employee safety as result of real-time monitoring and proactive prevention of instances where hazardous conditions were detected.

By connecting INTRANAV.IO to supply chain management and ERP, EWM systems, real-time information triggers further processes, allowing immediate response to fluctuations in material availability or manufacturing capacity.